Tapered roofing insulation panels are commonly used on flat and low-slope roofs and usually channel water to a roof drain or gutters. Any roof system, even those that look flat, actually have a small slope that prevents water from pooling before it reaches the drain or gutters.

In modern construction, the required slope for the roof can be a part of the framing process, but generally the tolerances are too small for framing. If the roof is extremely large, the slope can be ⅛” on the low end, yet over 12” on the high end.

Depending on the design of the structure, these tapered panels can be used in new construction, remodels, and to correct drainage issues. Tapered panels can be used to build crickets, which channel water over small and large areas.

Here we will discuss what tapered roofing insulation panels are used for, what they do, and why they are used.

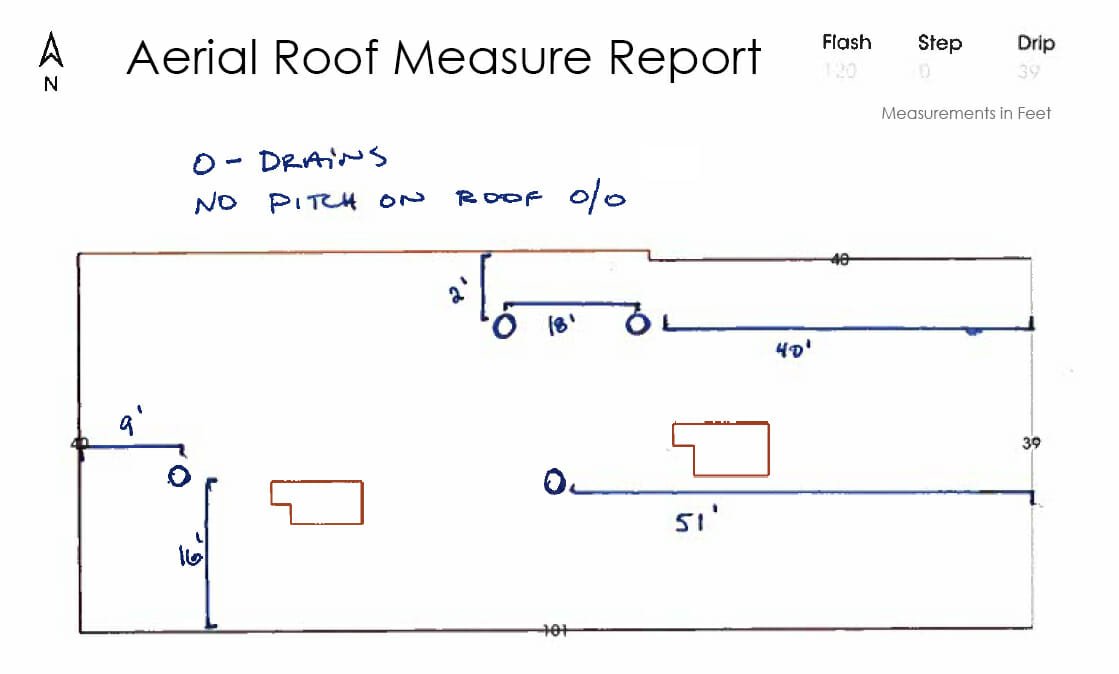

Aerial Measure Report for a fully-flat roof. All water shedding will need to be built out with taper panels directing toward scuppers along the outside wall.

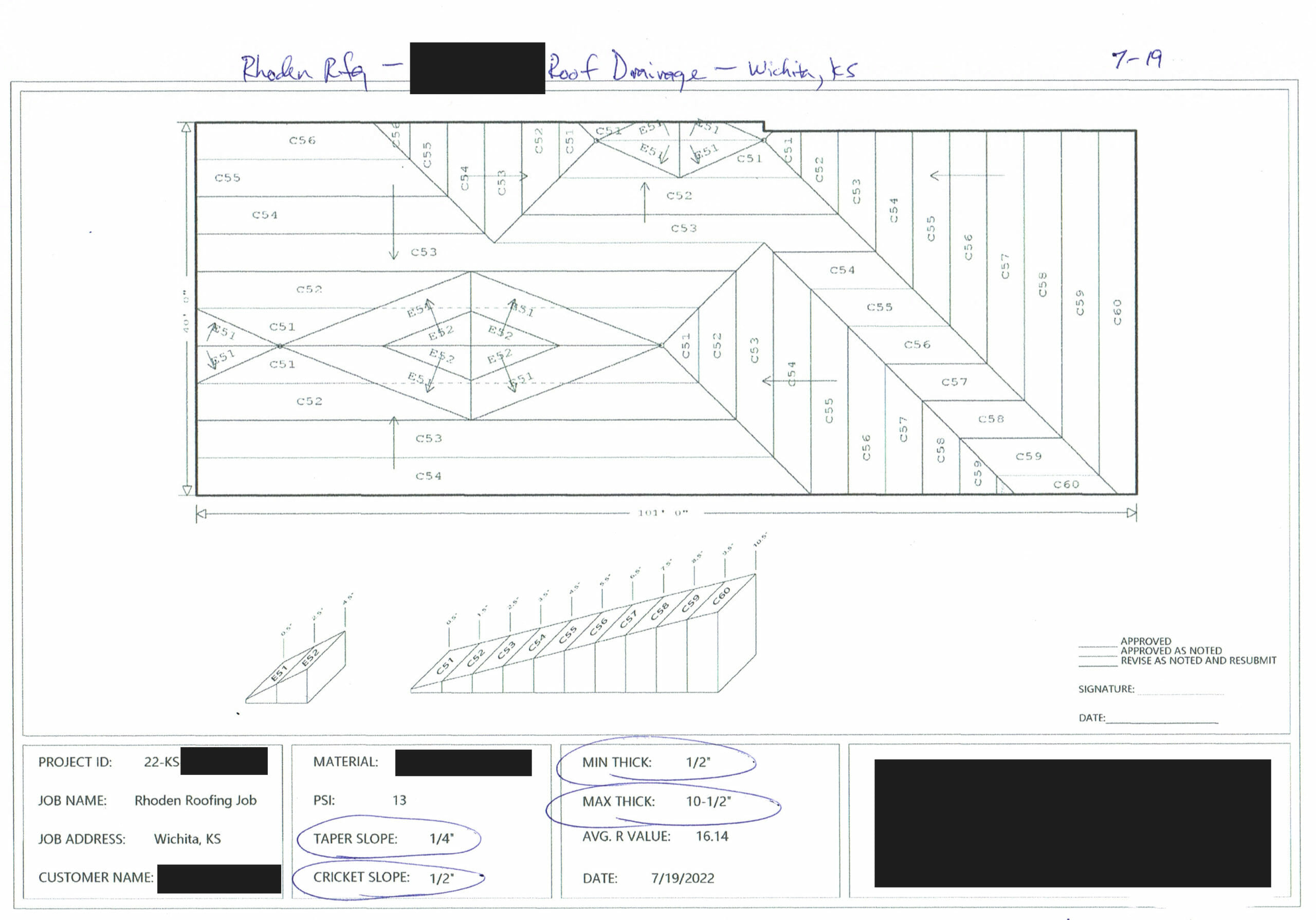

Taper diagram showing built-up crickets for water drainage – shown on the same roof as above.

What Are Tapered Roofing Insulation Panels Made Of?

Most tapered roofing insulation panels are made from a dense, closed cell foam called Polyisocyanurate. Polyisocyanurate tapered roof panels may include the roof decking, a foil or film backing, or a vapor barrier. Some tapered roof panels include a backing which serves as the substrate for the roof material.

Generally, polyisocyanurate, or Poly-Iso as it is known in the industry, is available in both standard, flat 48” x 96” sheets, or smaller 48” x 48” tapered sheets. Flat sheets of poly-iso are usually easier to install because they are larger and require little modification beyond trimming.

What Is the Most Common Use For Tapered Roof Insulation Panels?

Tapered roof panels are commonly used to increase the pitch of a sagging roof and to create crickets wherever they are needed, based on the velocity and volume of the water. Tapered roof panel systems are often designed by the manufacturers of the material.

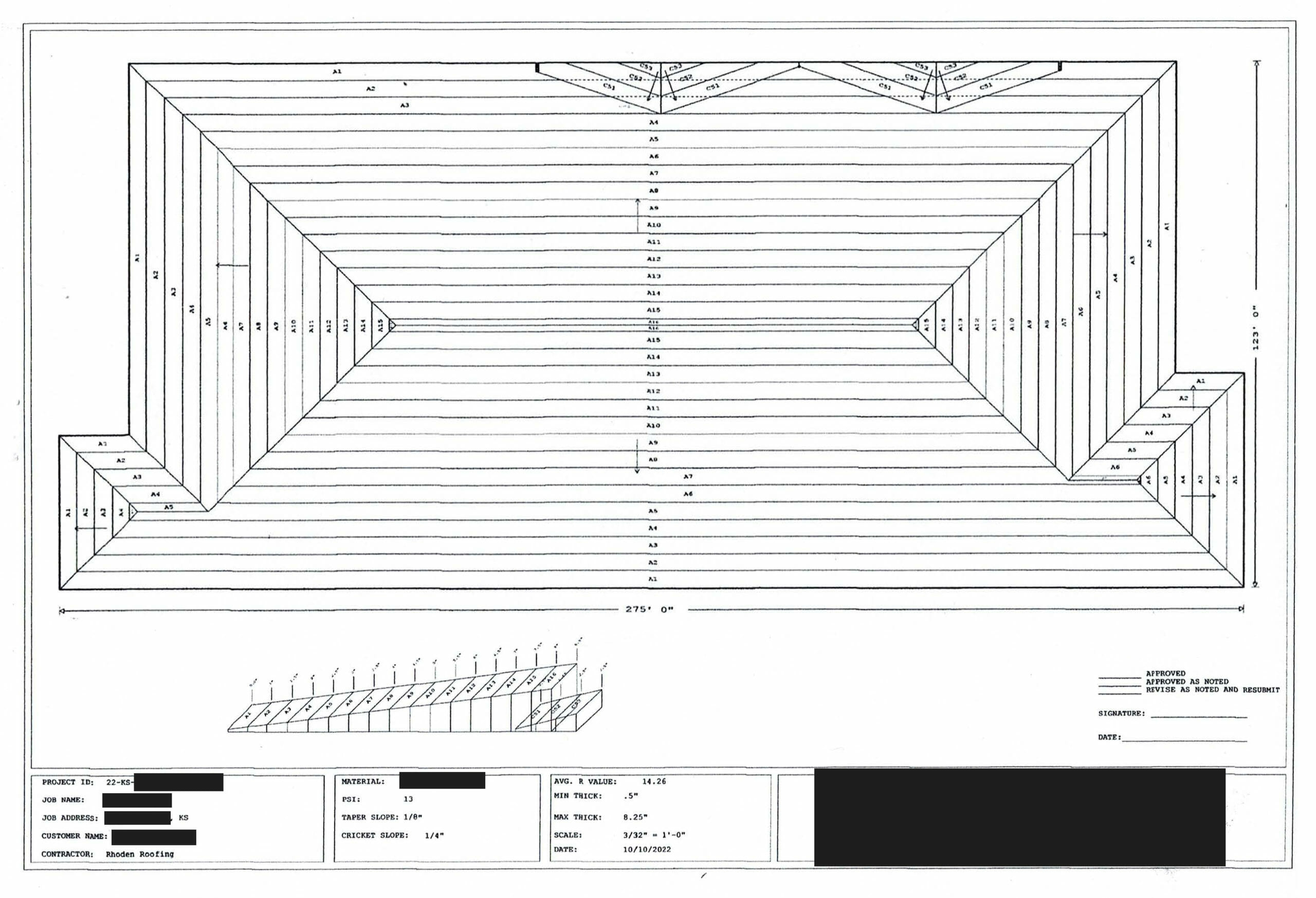

Some roofs, especially large commercial structures, are very complex and may include drain systems, crickets, and obstacles like AC units. Depending on how many panels will be required, the manufacturer will often provide a color coded map with detailed installation instructions.

Tapered roof systems are lightweight, so they can often be added to a roof without requiring additional framing support. This makes tapered foam panels popular with building owners and managers because they can be installed quickly, minimizing the impact to business activities.

Can Professionals Give My Flat Roof a Slope Using Tapered Roof Panels?

Professional installers can solve virtually any drainage problem caused by a poorly sloped, poorly draining roof using tapered roof panels. Flat or low slope roofs that have sagged can be corrected using tapered panels over the old roof and under the new one.

There are limitations of course, but troublesome flat roofs that allow pooling water can be corrected by adding just a few panels in strategic locations. Even enormous retail structures can be effectively protected with tapered roof insulation panels because the panels are so versatile.

As mentioned earlier, not all roof insulation panels are tapered. Some are completely flat and built up in layers, depending on the need. Tapered roof panels do the same thing, but unlike the simple arrangement of flat panels, tapered panels are more like a jigsaw puzzle.

So much so that manufacturers label them with typical “X” and “Y”, and “Z” labeling. Some tapered systems are even more complex and add interlocking edges. All of these features are to make the system more effective and do the job it was designed to do.

Can Tapered Panels Be Used With Both Drains and Gutters?

Tapered panels are very adaptable and can be used to direct water to a drain or gutter system. Many commercial building roofs have a central drain, or drains, which can be in the center of the roof and drain from a scupper on the side of the structure.

Other, more traditional commercial structures are often converted homes or are designed to offer a particular curb appeal. These buildings are more likely to have gutters, so tapered roof panels can be used to build hips and crickets wherever you need them.

What Is the Downside to Installing Tapered Roof Insulation Panels?

As with many great products, the downside is the initial cost. Some tapered roof insulation systems can be purchased for $1.60 to $1.80 per square foot, but many commercial buildings are also very large. Some roofs can exceed 30,000 square feet, resulting in a $50,000 investment.

However, investing in a tapered roof system may be a smart purchase, especially for businesses open at all hours. These buildings benefit the most from energy cost savings, so over time, the additional R value of the panels can provide a substantial return on investment.

Why Are Tapered Roof Panels So Common On Commercial Buildings?

Commercial buildings commonly have flat roofs to save money and provide additional space for other systems, like the HVAC equipment and generators. Some structures are so large the roofs would be impossible to maintain if they were shingled.

Low slope roofing materials like EPDM, TPO, and self adhesive bitumen are common on commercial roofs, but they only work if the roof drains. Tapered roof panels can be installed around corners, drains, used for crickets, and any number of other uses.

Can I Install Roof Decking Over Tapered Roof Panels?

Depending on the material your tapered roof panels are made from you may need to install a ½” foam board over the panels (EPS) before installing underlayments for radiant barriers. This protects the tapered panels, adds R value, and may be required by the manufacturer.

Most tapered roof panels can be used with most common low slope materials, but check before purchasing. A local pro can walk you through the options, make a site survey of your roof, and recommend the most effective choices.

Tapered solutions diagram showing panel layout on a larger flat roof – in this case 30,300 square feet – which requires double layers of paneling at the highest point. This particular roof required 8.25″ maximum thickness of taper panels in the center of the building.

This article is part of our ‘Low Slope and Commercial Materials’ Series. Learn more about:

System Types and Surface Materials

- TPO vs EPDM

- TPO vs PVC

- Mechanically Attached vs Fully Adhered Roofing Systems

- Black Roofs vs White Roofs

- Is a Metal Roof Right for My Commercial Property?

- Can a Commercial Roof Coating Save Me Money

- 3 Best Commercial Roofs in Wichita, KS

Substrate Systems

- Polyiso Insulation vs EPS Insulation

- What Do I Need to Know About Tapered Roofing Insulation Panels?