What Is a Pipe Boot & What Does it Do?

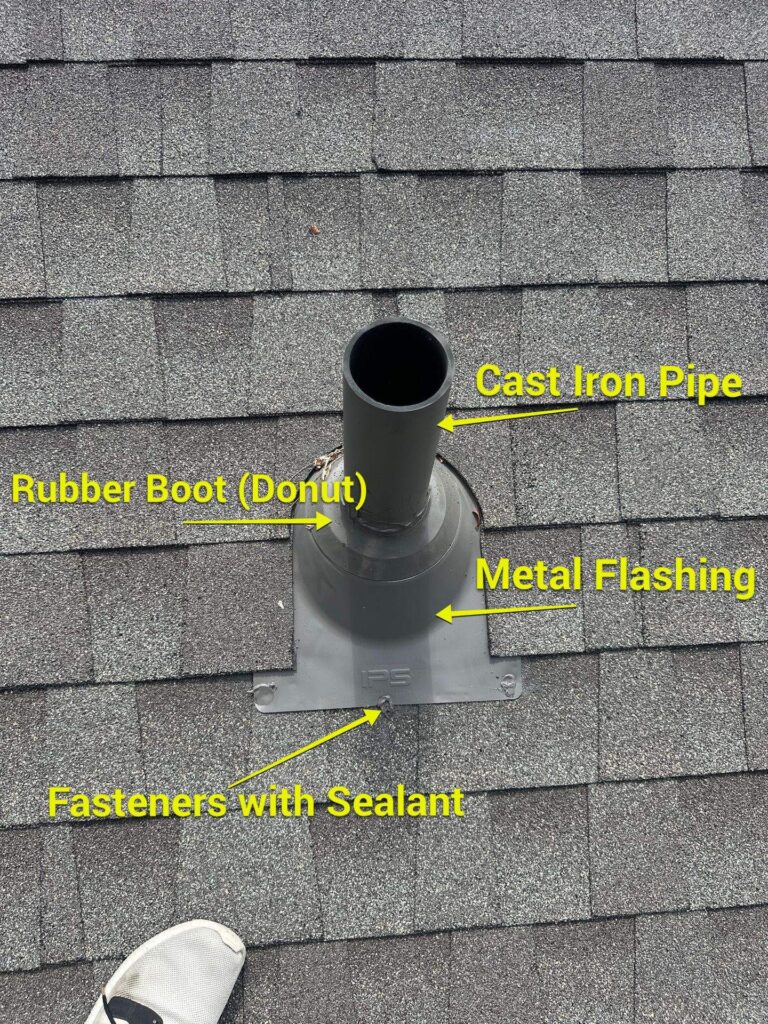

Also called pipe jacks or pipe flashings, pipe boots provide a watertight seal between pipes or other round roof terminations and the roof itself. They are used to seal plumbing vents, radon exhaust vents, bath fan terminations, and some miscellaneous items found on the roof. Pipe boots are made rubber (either EPDM or neoprene), plastic (typically TPE or TPO), silicone, or metal. They consist of a dome or cone-shaped collar that connects to the pipe above, and a flat base flashing below that interlaces with the rows (called courses) of shingles on the roof itself.

Note that heater flues – for furnaces, hot water heaters, or gas fireplaces – are treated separately because of their size, shape, and material. See our separate article on heater flue flashings.

Expected Service Life of a Pipe Boot

While manufacturing material and quality certainly vary, pipe boots are the #1 component that is likely to fail in less time than the lifespan of the primary field shingle of the roof itself. Baked by the sun, roofs are a hostile environment. Rubber pipe boots have the shortest life cycle, as the rubber material dries out with UV exposure. Often, rubber pipe boots need to be replaced after 10 or 15 years, and may need a compression “donut” sleeve added after as little as 5-10 years to stay watertight.

There is also the challenge of reused flashings – as we frequently find that discount roofing companies leave the existing pipe boots and other flashings when a roof is replaced, leaving a disparity in age of the components/materials keeping water out of the building. Finally, as the expected lifespan of roofing shingles has increased thanks to technological developments over the last 40-50 years, pipe boots have largely remained the same, meaning that many roofing materials (especially premium composite/synthetic shake/shingle/tile roofs) outlast the pipe boots.

Because of these factors above, it’s important to be aware of the condition of your existing pipe boots and have a realistic sense for expected remaining lifespan based on current conditions. Thankfully, maintaining or replacing a pipe boot is a relatively simple roofing job.

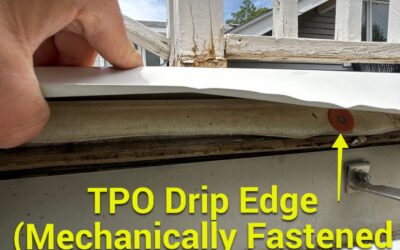

A rubber pipe boot on an asphalt shingle roof that is in good condition. Exposed fasteners can be treated with sealant, but the PVC pipe, rubber boot, and metal base flashing have years of service life remaining.

Evaluating & Addressing Pipe Boot Condition at Different Lifecycle Stages

0-5 Years: New Installation – Evaluating for Correct Installation

New pipe boots are usually black, and sometimes white. For the first few years, the surface will be smooth and the color crisp and consistent. If you have new pipe boots, you can check a few things to know if they were installed correctly. Some common errors we see with pipe boot installations that you can look for are:

-

- Shingles on the row (course) above are not cut away from the conical collar. There should be at least 1” of the flat flange showing above the boot. This keeps water from pooling at the site, and keeps the rough edge of the shingle from degrading the softer membrane material of the boot

- Exposed or loose nail heads. The nails on the flat flange upslope of the boot should be covered by the interlaced shingle courses. The nails on the flat flange below the boot should be covered with caulking or roofing sealant. If the nail heads are not properly sealed, or are loose, take a look at our article on How to Properly Caulk Exposed Nail Heads for info on material compatibility and best practices with roof sealant.

- Incorrectly sized boot. Most boots have the size or size range of pipes they are rated to fit printed or embossed on the collar. If that isn’t a match with the actual pipe, it may still look like a tight fit while it’s new, but over time the stress of added tensions can cause rips, or too loose of collars can roll or peel back. Double check early on, as we sometimes see the same size boot used across a whole roof even when different pipe sizes are present.

- Incorrect roof pitch. Steeper slope (pitch) roofs require a steeper angle of flange to avoid strain on the flexible pipe boot material. Similar to the pipe size, most manufacturers print or emboss the pitch rating on the boot. This is usually given as a range, either in degree angles or pitch rise over run, e.g. 2/12-8/12. You can also see our article on Roof Pitch and Multiplier. Assuming the pipe is mounted vertically, check that this matches your actual roof pitch. Typically the only time we see that this is wrong is when multiple pitches are present on one home and the original installer did not accommodate, such when there is a steeper turret roof, or shallower garage/patio roof.

- Pipe too short. This is most common with plumbing vents, which are identifiable as straight PVC or ABS pipes sticking up through the roof with no cover. A cover is not needed on a plumbing vent, as rain will simply go into the drain system, but they should extend at least 6” up (and more if you live in an area with more snow or where local building code requires it) to prevent snowfall from blocking the venting of the pipe. If your pipe itself is too short, contact a plumber – sometimes a simple extension can fix the problem – other times it will have to be re-run from inside the attic.

- Wrong roofing material type. Hopefully you don’t run into this, but it’s worth knowing that pipe boots are made for the specific roofing type. For example, an R-panel metal roof will need a compatible pipe boot designed to interlock with the grooves of the metal, and tile roofs mounted on purlins require compatible flashing boots.

A painted pipe boot with discoloration of the pipe, boot, and metals.

5-10 Years: Normal Weathering – What to Monitor

With prolonged exposure to the sun/UV radiation, signs of age will show up on the flexible boot material itself first. The base flashing metal should still be in good shape. Some minor maintenance and monitoring is recommended to avoid risk of water intrusion into the home. The definition of a successful roof is simple; keep water out. If the symptoms below describe your pipe boot, then it is still performing it’s one job, but some maintenance is recommended to make sure its lifespan is as long as the primary roof around it.

- Color Fading: New pipe boots are typically black, sometimes white. Within a few years, black boots will begin to gray, while white boots develop a dull, blotchy appearance. These changes are cosmetic, but they’re the first signs of UV wear.

- Texture Changes: The membrane loses its original glossy appearance and feels dry to the touch. Rubber membranes often develop a chalky residue that rubs off when touched.

- Surface Cracking: Sun-exposed faces of the boot may develop fine cracks on the membrane. While shallow, they are an early sign of progressive wear.

- Staining on Metal Components: The metal base flashing may develop staining, either as white mineral deposits from coating breakdowns or as small patches of reddish-brown oxidation — an early sign of rust.

Maintenance: Cleaning and Resealing with Donut Sleeves. If the membrane (soft part around the pipe itself) still looks good, you can clean dirt and plant debris off the pipe boot, which tends to accumulate in folds of the upper cone. We recommend against applying any kind of oil – which was once believed to prolong the life of rubber products – to the boot, as it has actually been shown to deteriorate rubber by increasing UV susceptibility, holding dirt or organic debris onto the surface which prolongs water exposure, and can affect chemical bonding of sealants if needed down the line.

If your rubber cone on the pipe boot is showing signs of surface cracking, we recommend adding a ‘donut’ compression sleeve over the existing pipe boot. This is a cheap, non-invasive fix that will protect the surface below and should keep the roof penetration leak-free for another 5-10 years.

Especially where the top of the membrane meets the pipe itself, it is good to clean the area and then apply a quality roofing sealant that is chemically compatible with both materials. Most vent pipes and radon pipes are PVC or ABS, and most bath fan terminations are either PVC or steel – all of which are typically compatible with almost all sealants. However, the membrane of the pipe boot is more important to make sure of chemical compatibility with the sealants.

Be wary of brittleness. Handle the materials with care. Pipe boots must be flexible when installed to fit over the pipes, but the same materials turn brittle over the years when exposed to UV. This is typically not a problem, as they don’t really have to move under normal circumstances, but do be aware while cleaning or working around a pipe boot that it’s certainly possible to do more harm than good, especially if you try to manipulate the folds of the boot and end up creating a crack.

10-25+ Years: Failure & Replacement – Knowing When It’s Time

The functional life cycle of a roof component is determined by its ability to keep water out. The transition from normal aging to concerning wear isn’t always clear. Some pipe boot materials, particularly silicone, can have a dramatically longer life cycle than the rubber boots detailed above. Still, on almost any roof, the pipe boots and penetrations become one of the earliest failure points with regards to keeping water out. We created an inspection checklist to standardize our recommendations, ensuring that replacement is only suggested when it’s necessary. Similar to how an insurance adjuster defines “totaled” on a car, we only recommend component replacement when the cost to replace a component or roof is less than the potential cost of damages over the next 12 months.

Based on our experience identifying and fixing roof leaks on over 13,000 homes and buildings, here are our criteria for when we recommend replacement of pipe boots:

- Cracks more than ¼” deep anywhere on the surface

- Any splits along the collar opening where it meets the pipe

- Corroded metal deterioration with active pitting rust

- Abrasive damage more than half the thickness of the material – such as from a branch falling or maintenance error.

- Water intrusion – If any amount of moisture is weeping through the barrier along the pipe and into the building, the pipe boot needs to be replaced. Signs of water inside will be visible as discoloration to surrounding wood or insulation, grime lines or staining on the pipe itself within the attic, mold, or spots on drywall below.

This article is part of our ‘Roof Component Inspection & Service Life’ Series. Learn more about:

Roof Covering

Flashing

Roof Vents

Roof Drainage