As you consider roofing options for a new build or for re-roofing an existing commercial property, there are many options to choose from. In the southwestern United States, a black roof membrane, like EPDM, is uncommon. In the northern Midwest, where a black roof covering’s heat retention can reduce energy bills, EPDM is nearly as common as TPO – the preferred membrane for many low slope roofing contractors.

Metal roofs, by contrast, are viable in almost any climate for low slope and steep slope applications.

This article is a practical guide for building owners and managers weighing a metal roof investment for their property. We’ll explore how considerations like noise, visibility, snow management and budget influence whether metal is the right choice for your commercial roof.

What Are Commercial Metal Roofs?

A metal roofing system consists of overlapping panels or shingles which will be fastened to either open framing or a solid substrate. There are multiple different styles of commercial metal roofs that are available for Wichita property owners.

How to Choose the Best Commercial Roof in Wichita

When you’re choosing which roof to install on your property in Wichita there are a few important factors that you’ll want to carefully consider to make the best decision for your business. Two factors will influence every building owner’s decision: budget and climate.

Commercial Roof Cost & Budget Planning

Most commercial property owners will readily admit that their bottom line is their number one priority when making decisions for their business. Your budget is the best place to start when deciding on a new roof, whether it’s for a commercial property, residential property, or even a doghouse.

Because a roof is a long-lived asset, many commercial property owners don’t view it as a cost but rather as an investment to be amortized across 10, 20, or 30 years. What matters is the lifecycle cost, which includes emergency repairs, downtime, and residual value – not just the initial price. Of course, many factors can preclude a building owner from a long-term CapEx lens: budget cycles, intent to sell, unexpected HVAC expenses, staffing shortages – sometimes a larger initial investment, even if it reduces operating expenses for the next 25 years, is not possible.

Metal roofs typically carry a higher upfront cost than alternatives like membranes or asphalt systems. But its reduced maintenance needs, extended lifespan, and performance make it a worthwhile consideration for property owners and managers.

In other words, if you’re planning one or two budget cycles ahead, a metal roof can appear prohibitively expensive. If you’re looking through a 30-year lens, the investment is often stronger than lower-cost systems that will require more frequent replacement and more extensive maintenance, in some cases.

How Climate Affects Commercial Roof Choice

If budget sets the decision boundary, climate sets the performance baseline.

When you choose a roof for your commercial property, you’ll want to consider the Wichita climate and weather patterns to make sure your new roof can reliably protect your building and prevent potential operational disruptions.

Regions with high sun exposure will benefit from improved energy performance, which has the potential to offset some of a metal roof’s initial cost with a reflective (high albedo coating or finish) metal roof.

Kansas weather is more volatile, with freeze-thaw cycles, hot summers, and heavy storms. The right roof for Kansas’ climate is less about short-term efficiency and more about long-term resilience. Each of these elements can be addressed by a well-engineered metal roof.

Most low-slope roofs we install in Wichita use a TPO membrane. It’s affordable, durable with a solid cover board (see What Is Cover Board and When Does it Make Sense to Include in a Low-Slope Roofing System for more information) and the right fastening method (see Mechanically Attached Vs Fully Adhered Roofing Systems for a detailed breakdown of low-slope fastening methods), and offers excellent energy efficiency. TPO is also flexible enough to tolerate freeze-thaw cycles without cracking or becoming brittle, similar to EPDM.

Beyond climate and budget, low and steep slope roofs have considerations that must be weighed before deciding on a metal roof. Membranes are ubiquitous in low-slope commercial roofing in Wichita, but metal might be optimal in the right circumstances. The following considerations will help you determine if a metal roof is the best choice for your property.

Steep Slope Commercial Metal Roof Considerations

| Consideration | How It Impacts Roof Choice | Is Metal a Good Choice? |

|---|---|---|

| Visibility & Profile – My roof is a prominent visual element of my building. | Metal and shingle roofs offer distinct profiles. Many new constructions accent asphalt roofs with a metal gable roof at the entrance or back for its appearance and color options. Standing seam offers clean lines, while shingle-style panels like Decra mimic traditional shingled roofs. | Yes. Metal roofs provide profiles and finishes that complement many architectural styles. |

| Snow Management –Snow and ice accumulate in my climate, so sliding is a concern. | Steep metal roofs shed snow quickly and often in large, dangerous slabs. Snow guards or retention systems are usually required for safety. See our article covering snow guard necessities to learn more. | Yes, with snow guards. Commercial buildings assume the liability of potentially dangerous slabbing, making a snow retention system a necessity. |

| Thermal Movement & Appearance – My climate experiences frequent freeze-thaw cycles and high summer heat. | Metal panels expand and contract with temperature swings. On steep, publicly visible roofs, this can cause noticeable waviness, called oil canning, especially with lighter colors. | Maybe. Floating clip systems, heavier-gauge panels, and ribbed profiles can minimize oil canning and preserve the panels’ appearance. Asphalt roof systems, with proper underlayment and ventilation, perform well with frequent freeze-thaw cycles. |

| Maintenance & Access – My roof requires periodic inspections, cleaning, or frequent rooftop access. | Steep metal roofs with a 6:12 pitch or greater can be slippery, making access difficult and dangerous. While asphalt shingles allow for greater traction, they risk granule loss with frequent foot traffic. | Maybe. An exceptionally steep metal roof with a 9:12 pitch or greater is nearly impossible to repair without additional equipment. Ensure that your roof is accessible for any necessary maintenance to reduce both costs and risks in the future. |

| Fire & Hail Ratings – My building needs high fire & hail resistance ratings for insurance, safety, or code compliance | Most metal roofs are inherently class 4 impact resistant, while asphalt roofs can be impact resistant. Both maintain a class A fire rating. | Yes. Metal roofs are consistently Class 4 impact resistant and Class A fire rated. Large hail strikes may cause cosmetic denting, but metal roofs generally maintain performance better than shingles in hail-prone climates and may reduce long-term storm-related insurance claims. |

Low Slope Commercial Metal Roof Considerations

| Consideration | How It Impacts Roof Choice | Is Metal a Good Choice? |

|---|---|---|

| Visibility – My roof is visible from highways, neighboring buildings, or the ground. | TPO’s bright white surface has a high initial albedo, which can create intense glare for a few years after installation and make dirt buildup more noticeable. Metal roofs are typically finished with PVDF (Polyvinylidene Fluoride), which can mitigate its reflectivity and the conspicuity of dirt. | Yes. Metal is more aesthetically flexible. While alternative colors are available for TPO, they can be prohibitively expensive and sacrifice potential energy savings. Metal roofs have myriad color options, rib heights, and distances for comparable prices. |

| Customer-Facing vs. Industrial Use – My building does not receive frequent customer traffic (e.g., manufacturing facility, warehouse, and distribution center), or regularly receives customers (e.g., church, retail, and multi-family). | Noise from rain or foot traffic is amplified by metal roofs without drop ceilings and/or insulation. Weather-related noise is less of a concern for non-customer-facing businesses, while acoustics are a consideration for buildings with tenants or customers. | Yes for industrial buildings, maybe for buildings with frequent customer traffic or living spaces. Steel panels can amplify sound like a drum, although insulation layers dampen noise like stuffing the drum with padding. Durability and maintenance frequency often matter more for industrial buildings than acoustics. |

| Energy Efficiency – My priority is lowering cooling costs in the summer. | Metal roofing reflects solar radiation and supports white roof coatings, but those incur an additional expense. TPO naturally offers high reflectivity. | Maybe. Metal is thermally efficient, especially with reflective coatings or finishes. However, TPO generally delivers higher reflectivity at a lower upfront cost. |

| Fire & Hail Ratings – My building needs high fire & hail resistance ratings for insurance, safety, or code compliance. | 24 gauge or thicker metal is recommended for commercial properties to minimize denting, but almost all metal roofs are class 4 impact resistant and class A fire rated. TPO’s hail rating is determined by its mil thickness, whether it’s fleecebacked or not, and the substrate below it. Its substrate and securement method also influence its fire rating. | Yes. Metal roofs reliably outperform standard membrane roofs in impact and fire rating tests. |

| Structural Strength of Building – My roof requires R-30 or has decking limits. | Metal roofs that require insulation may require solid decking reinforcement between the roof and structural members, increasing its cost. Deck reinforcement may also be necessary to handle dead loads. | Maybe. Verify deck capacity and insulation needs before selecting metal. |

| Rooftop Equipment & Penetrations – My building has multiple HVAC units, vents, and other rooftop equipment and penetrations. | Penetrations are the most likely source of leaks. Membranes weld or patch more flexibly. Metal roofs typically use rubber, EPDM flashings to improve flexibility and reduce the risk of thermal expansion and contraction affecting flashings. These often have exposed fasteners, which require regular resealing. | Maybe. Metal can perform well with meticulous detail work, but an abundance of penetrations favors membranes for reduced maintenance. |

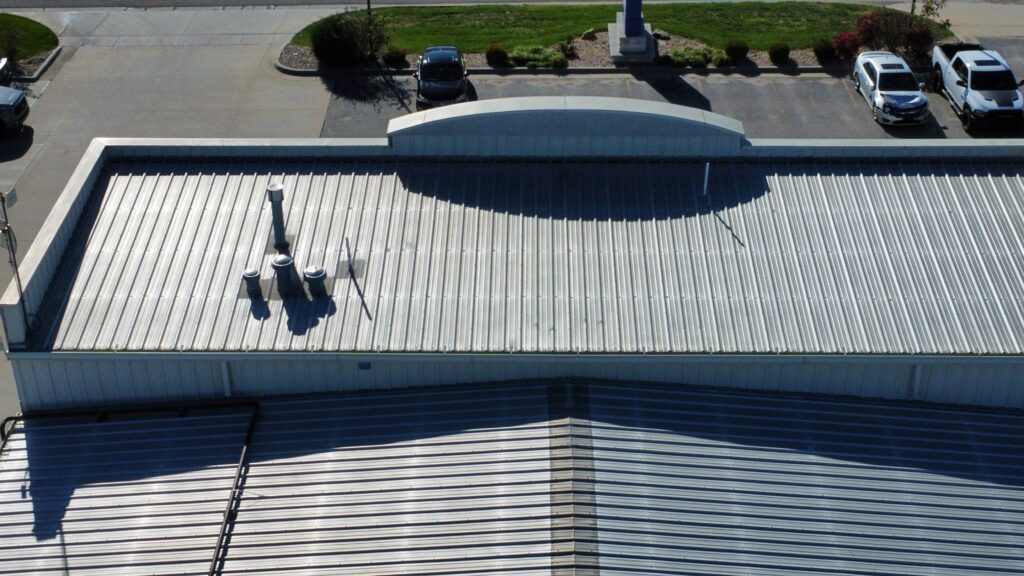

A TPO roof installed by Rhoden Roofing in Wichita, KS. This project did not require significant tear-off, as we were able to layover a new TPO membrane on the previous roof system. A metal roof system can be retrofitted, but it was not viable for the property owner here.

Choosing the Right Commercial Roof

The right commercial roof can’t be identified by selecting boxes on a checklist. It’s a weighted balance cost vs. savings, climate, and the building’s purpose, among many other considerations. Metal may be the right choice, but so can membranes or asphalt shingles, depending on your priorities.

What matters most is making a decision with a clear understanding of potential trade-offs. A roof isn’t a simple line item on a budget: it’s an investment that influences your property’s performance, appearance, and maintenance needs for decades.

This guide is a framework for weighing these factors. Every building is different, but the more informed you are, the better prepared you’ll be to choose a roof that aligns with you and your building’s long-term needs.

If you still have questions about which roof system to use for your commercial property, we’re glad to share what we’ve learned from decades of installing and maintaining commercial roofs. Reach out by calling us at (316) 927-2233 to review your building’s needs and get guidance on next steps.

This article is part of our ‘Low Slope and Commercial Materials’ Series. Learn more about:

System Types and Surface Materials

-

- TPO vs EPDM

- TPO vs PVC

- Fleeceback vs. Standard Membranes for Low-Slope Roofs

- Mechanically Attached vs Fully Adhered Roofing Systems

- Black Roofs vs White Roofs

- Is a Metal Roof Right for My Commercial Property?

- Can a Commercial Roof Coating Save Me Money

- Flat Roof Coatings – What Are They and When Are They Appropriate?

- 3 Best Commercial Roofs in Wichita, KS

- What Is a Flute-fill Retrofit on a Commercial Metal Roof and When Does It Make Sense?

- Retrofit vs. Replacement: What’s the Best Option for Your Commercial Metal Roof?

- Fleeceback vs. Standard Membranes for Low-Slope Roofs

Substrate Systems

-

- Polyiso Insulation vs EPS Insulation

- What Do I Need to Know About Tapered Roofing Insulation Panels?

- What Is Cover Board and When Does it Make Sense to Include in a Low-Slope Roofing System?

- DensDeck vs Fiberboard: Which Cover Board Is Best for Low Slope Roofs?

- Commercial Roof Decking Guide: Comparing Wood, Metal, & Concrete for Low-Slope Roofs