Introduction

Cover board is an optional layer in low-slope membrane roofing systems that sits on top of insulation to provide a more rigid substrate before the top membrane layer. In general, we typically recommend cover board where possible. However, it is not always required by building code, and we will help you understand the cost and install implications to be able to make the right decision for you and your building. There are also many cover board options and products available, so we will start to explore the differences between different styles and what applications make the most sense.

In this article we will help you understand what cover board is, why it’s important, why we recommend cover boards to the majority of our clients, and illustrate the few situations in which cover board is not essential.

What Is Cover Board?

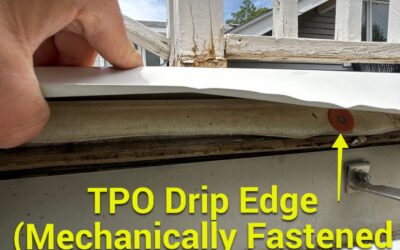

Cover board is typically a thin, dense board (aka substrate) that is placed over decking or insulation to provide a stable, flat surface for the top layer of waterproofing material, and to protect the softer insulation below. Cover board can either be glued down using adhesives, or it can be mechanically attached using screws and metal plates.

What Types of Cover Board Do We Recommend?

While there are numerous options available, there are two that we trust and recommend most often for our flat and low slope commercial clients: High-Density (HD) Poly ISO Board, manufactured by MuleHide, and DensDeck®, Manufactured by Georgia-Pacific Gypsum LLC, which is a mat-faced gypsum board. Both are particularly well suited to commercial roofing applications. For us, these two products work for most of our use cases, making them our go-to recommendations.

HD Poly ISO Board: Also known as high-density polyisocyanurate, HD Poly ISO board is made of a high-density, closed-cell poly ISO foam core that is bonded on both sides with inorganic fiberglass mats. The result is a dense, yet lightweight gypsum-based cover board that can perform well in a wide variety of applications. We usually use a product that is 1/2” thick, has an R-value of 2.5, and has a 100 psi compressive strength. MuleHide, the company who manufactures it, has been making quality roofing products for 120 years.

DensDeck®: Manufactured by Georgia-Pacific, DensDeck® has become a staple in the commercial roofing industry. The gypsum core is sandwiched between fiberglass mats on both the top and bottom of the board. These fiberglass mat facings are embedded into the gypsum core, creating a patented design that enhances the board’s performance. This produces a dense and heavy board that is fire resistant, water resistant, mold resistant, impact and puncture resistant, and wind uplift resistant, with a high level of dimensional stability (rigidity). It is available in 1/4”, 1/2”, and 5/8” thicknesses and 4’x4’ or 4’x8’ sheets. Due to its high-density gypsum core, the larger DensDeck boards can be heavy and sometimes difficult to maneuver on the job site.

What is the Point of Cover Board? What Are the Benefits?

- Smooth, Water-shedding Surface: Cover board creates a smooth, flat surface for the layer of single-ply roofing membrane that will be laid on top of it (such as TPO or PVC). Smooth seams for a flat roof are important for water runoff because any grooves, seams, ridges, etc become areas rainwater can collect and puddle. Speed is the name of the game when removing water from a roof because any time water is sitting against a membrane seam or roof penetration, it has a higher risk of seeping through. A well-installed cover board helps rainwater to quickly shed off the building.

- Protect Insulation from Foot Traffic: Cover board is more dense than insulation below. EPS foam insulation and Poly ISO insulating boards are two common examples of roof insulation. Insulation is typically effective because of trapped air pockets (which give it its insulating properties). However, that also makes it liable to crushing and damage from foot traffic, maintenance techs, work being performed on the roof, etc. A dropped hammer and dented insulation (without a cover board) means a divot that would retain rainwater and create a potential leak site. Any movement or stretching of the membrane itself is an opportunity for cracks or splitting.

- Protection from Hail: A high-quality cover board has both density and some amount of flexion, meaning that hail strikes are able to bounce, rather than embedding into insulation.

- Increased Thermal Performance: Although cover board is not designed to have a high R-value, it does provide an additional layer of thermal protection. The cover boards that we, at Rhoden Roofing, typically use come with R-values between R-2.5 to R-3.2. Higher R-value options are available upon request. In addition to the R-value of the cover board itself, it protects the insulation below from compression or damage preserves its ability to perform over time.

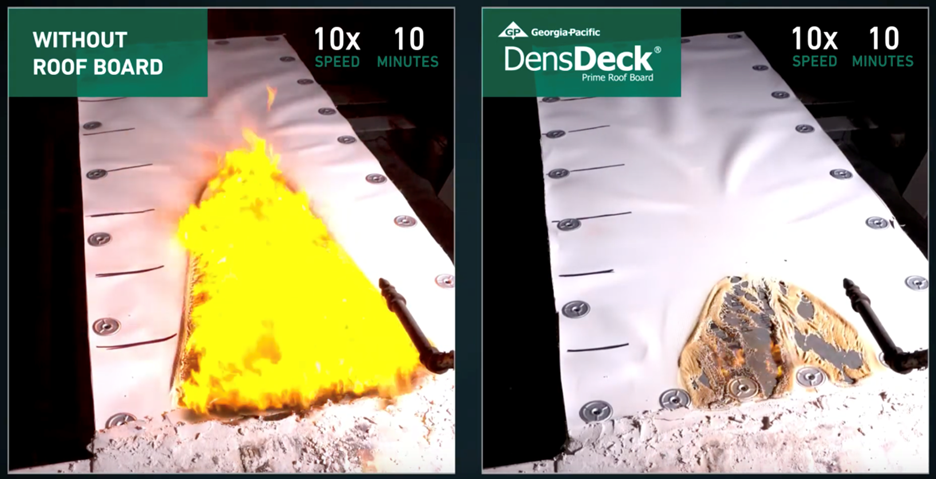

Source: DensDeck® Georgia-Pacific Building Products – youtu.be/idHue9Y6nJE?si=NFiRbmuoRHv2rOHN

- Improved Fire Ratings: Gypsum cover boards are classified as non-combustible materials. The gypsum core contains crystallized water that vaporizes when exposed to heat, helping resist fire spread. DensDeck®, a gypsum-fiber cover board made by Georgia-Pacific, boasts a flame-spread rating of 0 and a smoke-developed rating of 0. This is important because some insulation materials below can be highly flammable. A fire resistant cover board can slow the spread of fire from one building to another. For these reasons, some building insurance providers offer customers savings on their premiums if a fire resistant cover board is used.

- Protection Against Wind Uplift: Wind uplift (or wind pressure) refers to the upward force exerted on a roof when the wind blows over and around a building. Like the wing of an airplane, when air flows over the top of the wing (or flat roof), it creates a negative pressure system over top. A properly-installed cover board layer helps the waterproofing membrane resists wind pressure because it is attached to a stable, sturdy base.

- Longer Warranty: Some manufacturers of waterproofing membranes will not extend a 20-year or 25-year material warranty unless the roofing system includes a suitable cover board.

- Increases Longevity of Roof: Although every roof is different, we believe that the use of a high-quality cover board extends the life of your roof by increasing the resiliency of the waterproofing membrane.

When Might a Cover Board Not Be Necessary?

While we typically recommend using a cover board, there are a few situations in which cover boards are not essential. In these cases, a fleeceback waterproof membrane (like fleeceback TPO or fleeceback PVC) can be used in place of a cover board. The 55-mil thick fleece that is adhered to the underside of the waterproof membrane provides the stability and rigidity that a cover board normally would. Fleeceback options are often a great way to help customers save money and get their roofing projects done quickly. For more information, please see our article on fleeceback TPO vs Modified Bitumen.

A cover board layer may not be necessary in situations where speed and minimizing costs are the priorities. For example, after a hail and wind storm swept through the Great Bend region, our team helped design a new roofing solution for The University of Kansas Health Systems Great Bend Campus Hospital. The most important factor for this particular project was speed, and lack of downfall or interruption of daily hospital operations (including a helipad). The existing modified bitumen roof had been damaged by the golf ball-sized hail. Rather than removing their damaged modified bitumen roof, which would have been a lengthy and costly project, we were able to address some of the substrate damage, then lay down a single layer of fleeceback TPO waterproofing membrane. This minimized operational downtime and noise for the hospital, in addition to saving money relative to either a complete replacement or a cover board application. The full story of this particular project is covered in much more detail in a project highlight published by Professional Roofer Magazine, Critical Roofing: KU Health Trauma Center

What Other Types of Cover Boards Are on the Market?

While we typically trust the two products outlined above because we have the most experience with them and have time-tested trust in our own builds, here is a more complete list of the types of cover board options available:

High-Density (HD) Poly ISO Board: Made of a high-density, closed-cell polyisocyanurate foam core with high-performance coated fiberglass (CGF) mat facing on both sides.

Mat-Faced Gypsum Boards: Made of a gypsum core with fiberglass mat facings on both sides.

Gypsum Fiber Boards: Made from a homogeneous blend of gypsum and cellulose fibers without a fiberglass mat facer.

Wood-Based Cover Boards: Made from wood fibers or cane fibers that have been bonded together with resins. Plywood and OSB are two common options in this category.

Cementitious Cover Boards: Made of a cement-based core, often reinforced with mesh fibers.

Perlite Boards: Made from expanded perlite, cellulose fibers, asphalt, and starch binders, sometimes coated with a polymerized asphalt emulsion.

Asphaltic Core Boards: Made with an asphaltic core sandwiched between fiberglass faces.

Mineral Fiber Boards/Rock Wool: Made from mineral fibers (rock, slag, or glass) bonded with organic and/or inorganic binders. Excellent fire-resistant properties due to its mineral composition.

Summary and Key Takeaways:

- Definition: Cover board is typically a thin, dense board that is placed over decking or insulation to provide a stable, flat surface for the top layer of waterproofing material, and to protect the softer insulation below.

- Attachment Options: Cover board can either be glued down using adhesives, or it can be mechanically attached using screws and metal plates.

- Advantages: Cover board protects the insulation from foot traffic, dropped tools, and hail, increases thermal performance, improves fire ratings, decreases wind uplift, and extends the warranty and longevity of the roof.

- Popularity: Some popular cover board options include high-density (HD) Poly ISO board and DensDeck®, both of which are well-suited for commercial roofing applications.

- Key Takeaway: Due to its many advantages, we recommend the use of a high-quality cover board to the majority of our low-slope buildings.