Coatings Are Only Appropriate in Limited Situations

We want to be upfront by saying that in the majority of cases, we don’t think that roof coatings are the best solution for most flat and low slope commercial roofs. Over many years of inspecting, servicing, repairing, and replacing flat roofing systems, we simply don’t find them to be the inexpensive cure-all, fix-all solution that some roofing contractors (and coating manufacturers) tout. However, there are a few circumstances in which coatings do make sense and can be helpful in extending the life of your existing commercial roof.

In this article we will provide an overview of coatings and the different types available, and our own commentary for when coatings make sense and when they do not. As an installer of many types of roof systems (including coatings where appropriate), we don’t have any financial bias as to the final product selection and simply aim to help our customers find the best solution for their situation and roof. It is worth noting that there are roofing contractors with businesses that exclusively apply coatings – and while they may do good work, it’s worth acknowledging that coatings-only installers are financially incentivized to recommend coatings in more situations than we would advise.

The next ‘step up’ from a coating may be a layover. A layover is more expensive and more durable than a coating. While layovers have limitations, just like coatings, they’re generally appropriate in more situations. See more detail in Layover vs Remove-and-Replace On a Membrane Roof.

What Are Roof Coatings and What Is the Benefit?

The term “coatings” refers to a wide variety of thick, paint-like substances that are applied over the existing roof, creating an additional layer of protection from sun and weather. They can be applied to a wide variety of roof surfaces, including shingles, modified bitumen, single-ply waterproofing membranes like TPO and PVC, as well as various types of metal roofs.

In virtually every case where a coating is being used, it is done as a cost-deferring (we are careful not to say cost-saving) alternative to replacing the entire roof system. Sometimes this works to extend the life of an aging roof system that’s still in good condition and push the expensive, cash-flow-demanding roof project down the road a few years.

What Are the Risks/Downsides of Roof Coatings?

However, we frequently building owners that attempt to use coatings to repair an already-damaged roof that required replacement to restore its performance. Admittedly, if we’re getting a phone call about someone else’s work, it’s because something isn’t going well. But we find that coatings can sometimes be a temporary Band-Aid to bigger problems – or worse – seal in moisture in already-damaged roof systems and accelerate decline.

An example of a hastily-applied roof coating that covered debris and moisture on the roof, causing splits and a rough edge. Even when applied well, coatings rarely look good, or look good for very long. For this reason, they are not commonly done on visible roofs (e.g. lower lobby of a tall building or hotel), and if they are done as part of a real estate transaction, it’s worth knowing that the outcome is not likely to contribute to the visual appeal of the property.

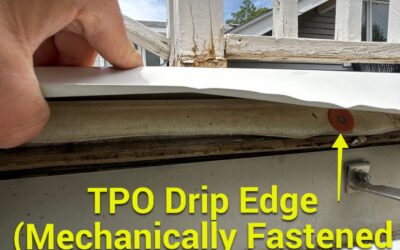

Coatings also need to be applied with care by an experienced contractor. If coatings are sprayed everywhere in haste (usually a cost-saving measure), the coating can get into places where it’s not wanted. For example, over-sprayed coatings gum up the notches in screws and fasteners, making them very difficult (and expensive) to remove when the time eventually comes to replace your roof, or adding labor time and cost to HVAC repairs or other work on the roof. Likewise, coatings should never be sprayed on, or applied to, mechanical equipment, roof-mounted generators, communication devices, roof terminations, or safety equipment. We have gone out on inspections to find prior coating jobs sealed roof hatches, sealed vent screens, plugged internal drains, coated access ladders, etc. One scary event on the west side of Wichita, our team went out to a metal-roof warehouse that had been coated and the fiberglass skylights had been coated over, creating an invisible minefield of possible places for workers to fall through. That was one of the rare cases where we declined doing any work on the property; the building owner had tried to save money, only to discover they had created an even bigger problem to be addressed within just 12 months of the original coating job.

When Do Coatings Make Sense For a Commercial Roof?

- The Roof is in Pretty Good Shape: Perhaps your roof is in good shape but it’s nearing the end of its life and you just want to help it last a little bit longer with a roof coating. We see this done when the business operating from the building doesn’t have the cash flow for a full roof replacement, but expects to in the future. This is an example of a cost-deferring measure.

- Selling the Building: If you plan to sell the building right away or within the next few years, a coating might make sense. Without a major investment, a coating can help a roof that’s in decent shape last a few years longer and give peace of mind to the new buyer.

- Energy Cost Savings: Many roof coatings are white, which depending on building use and insulation structure, will help to keep your interior spaces cooler, reducing cooling costs in the warm summer months. See more detail in our article Black Roofs vs White Roofs

- Warranty Protection: Coatings come with a wide variety of manufacturer warranties. Check with your roofing contractor for more information on the warranty for your specific coating. In our experience, the installation has to be flawless, and meticulously photo-documented for most manufacturers to honor a warranty – but when performed correctly, this can de-risk an investment property or help with building insurability.

- Tie Into an Existing Roof: Occasionally, when patching just a portion of an existing roof, it makes sense to use a coating to tie in the new section to the old section, ensuring there is no chance of water penetrating between two roof sections.

- Repairs: Especially if there is an existing coating, the only thing you can do to repair an individual section is to re-coat that area. This is relevant for leaks caused by moving mechanical equipment or falling branches, rather than system-wide failures like cracking membrane or flashing failures. The former is an acute issue, while the latter is representative of more wholistic system failure.

An effective use of coating to extend the life of this metal roof. The existing system was in reasonably good condition, and some of the curb flashings were repaired prior to coating.

When Are Coatings NOT the Best Option for a Commercial Roof?

- Coatings Are Not a Cure-All: No coating is going to fix a leaking roof for any meaningful amount of time. If your roof has existing problems such as active leaks, drainage/slope issues, structural problems, flashing issues, isn’t being regularly maintained, has membrane cracks/blisters, substrate issues (often showing up as loosening screws) – the roof likely needs complete replacement, or at a minimum, re-covering. Also called a layover, re-covering is more expensive than coating but less expensive than complete replacement. However, as with coating, it is only appropriate in some situations. See our more detailed article Layover vs Remove-and-Replace.

- The Wet Diaper Affect: If coatings are applied over existing moisture intrusion, that water will become trapped in the roof system. This can cause rot, corrosion, and mold. Coatings also are a poor fit with any roof that has ponding, puddling, or drainage issues. Standing water tends to behave like a magnifying glass to break down the coating layer and allow water underneath. Trapped water will evaporate and work its way up, causing the coating to loosen, bubble, and split.

- Disreputable Companies: Because coatings are typically used as a cost-deferring (and again, we are careful not to say cost-saving) method for delaying a replacement, price is typically the most important factor that building owners cite when making a decision. We find that this tends to make the marketplace of coatings installers a race to the bottom for who can do it the cheapest. We hear many stories about the cheapest bids also coming paired with misinformation and promises that coatings will solve all the roof’s problems. Unfortunately, the cheapest way to perform a coating job is to save on labor costs and spray indiscriminately – damaging HVAC equipment, sealing drainage, coating dust and debris into the roof, etc. With any coating job, the eventually roof replacement is just being deferred for a few years, so you don’t want to create problems that will make the inevitable complete replacement more expensive. Be especially wary on a metal roof, because the screw fasteners getting clogged with coating will make removal substantially more difficult. We recently added three days to a metal roof replacement on a medium-sized storage facility because each fastener had to be wire brushed by hand before a drill bit could engage to remove it. Multiplied by an 18-person crew, that’s more than 400 hours of additional labor just wire brushing coating out of screw heads.

“Alligatoring” is cracking caused by UV deterioration on the membrane or coating surface.

This extreme example of a chemical/product incompatibility makes for a fun (not actually fun) Holstein effect. In this case, the coating applied failed to bond with the black EPDM roof below.

What Types of Roof Coatings Are There?

If your building is an appropriate fit for a coating, the type of roof coating product that will best suit your particular situation and building depends on budget, goals, timeline for eventual roof replacement or building sale, and desired level of durability, along with other factors. There are several types of roof coatings available. As always, we recommend discussing with a reputable roofing contractor in your area to help you make the best choice for your unique situation.

Silicone Roof Coatings – What Are the Advantages and Disadvantages?

Improving silicone technology has shifted these types to be the most common coating (at least in our Lower Midwest region) in recent years.

- Waterproof: The polymers that make up silicone roof coatings are hydrophobic, which means water beads up and runs off, assuming that your roof surface is not completely flat. Silicone coatings resist ponding water better than elastomeric coatings because they do not absorb any additional water after they have cured. This might can be a good fit when the runoff slope is extremely low and the roof is aging but still in mostly good condition.

- UV Protection: Silicone coatings are typically white and can reflect up to 80-90% of the sun’s rays when clean or freshly applied. They do not chalk or break down over time and can withstand prolonged exposure to the sun. The white color can help to keep the surface of your roof cooler, as well as help to keep your internal spaces cooler in the summer. This can save you a significant amount of money in warm and sunny climates, especially if you have a dark EPDM or Mod Bit roof.

- Elasticity and Impermeability: When silicone coatings are applied with sufficient thickness, they provide an unbroken layer of resilient protection for your roof. Silicone can withstand heavy foot traffic, extreme temperature fluctuations, and impacts like hail and wind-driven sand, as well as endure the expansion and contraction of metal roofs. However, do not be fooled! If your roof has serious problems, such as leaking, cracking, structural issues, drainage problems, ponding, and the like, no coating, not even silicone, will solve your issues.

- Environmentally Friendly: Silicone coatings are considered more environmentally friendly, especially the thicker and more viscose formulations. Most of the top-quality silicone coatings are solvent-free and have low VOCs, which means they do not release a lot of harmful gasses into the atmosphere. Most silicones are safe to use in all 50 states by meeting and exceeding environmental standards.

- Technological Advancements: Thanks to silicone’s superior durability, compared to other coatings, many advancements have been made in recent years. Silicone products are quickly becoming the emerging leader in coating technology.

- More Expensive: Of the three primary types of roof coating, silicone products tend to be the most expensive per square foot.

Elastomeric Roof Coatings – What Are the Advantages and Disadvantages

The long-time dominant coating type, elastomeric coatings are still the most common to find on existing roofs, and still is very commonly used on new coating installs.

- Elasticity: As the name suggests, elastomeric roof coatings are made of elastic polymers that have stretchy properties. The elastomers that make them up have weak intermolecular bonds, which means they conform to fill the shape of whatever they are placed on top of, creating an unbroken layer of protection. Their molecular strands can coil and uncoil as the material below them expands and contracts.

- Metal Roof Compatibility: Of all roofing types, metal panel roofs expand and contract the most, so elastomeric coatings (that are specifically designed for metal roofs) are used. If the metal roof below expands more than the elastomeric coating, you can get cracking and splitting, which undermines your new coating.

- Waterproof: Elastomeric roof coatings are typically sprayed or painted on, creating a seamless layer of waterproofing protection. The elastomers that make them up are also hydrophobic, which means water beads up and runs off, assuming that your roof system has the minimum pitch of ¼:12.

- Reflectivity: Elastomeric roof coatings are typically white in color, so they reflect sunlight and can help keep your internal cooler in the summer.

- Extend Roof’s Lifespan: When properly applied, elastomeric roof coatings can extend the life of your roof for roughly 5 to 15 years depending on various factors. The primary factor in determining how long a coating will last is the thickness with which it is applied. When a coating is applied to an aged roof that has no major problems (like leaks, cracks, tears, deformation, corrosion, ponding, and puddling), elastomeric roof coatings can extend the life of your roof.

- Product Warranty: All reputable manufacturers of elastomeric coatings offer a manufacturer’s warranty. The advantage to you as a customer is that of peace of mind, knowing you won’t have to worry about your roof for a few more years. However, please keep in mind that all coatings are only as good as the material you apply them to, so they will not fix underlying problems.

Acrylic Roof Coatings – What Are the Advantages and Disadvantages?

The cheapest coating product option, and easier to install. Our team doesn’t have a very positive relationship with acrylic roof coatings based on our experience repairing and maintaining roofs that already have these products on them. The products themselves may not always be at fault; some still come with manufacturer’s warranties, and can last as long as 5-10 years. However, as mentioned above, roof coatings are typically used as a cost-deferring (we are careful not to say cost-saving) method for delaying a replacement, so price is typically the most important factor that building owners cite when making a decision. Often times that means that the marketplace of coatings installers is a race to the bottom for who can do it the cheapest. And the lowest quality install bids usually use an acrylic coating product – so it’s hard to differentiate cheaper installs from cheaper products.

- Cost: They are relatively inexpensive and last roughly 5 to 10 years under a broad range of climate conditions. Although acrylic coatings are often sold at affordable price points, they are losing ground in popularity to the more durable silicone and elastomeric coatings.

- Not as Waterproof: Acrylic coatings are water-based and they will eventually break down if exposed to ponding water for an extended period of time. When the sun’s rays hit and move through the water, they concentrate destructive wavelengths like a magnifying glass, shortening the life of an acrylic coating.

- Loss of Thickness: Acrylic is a sacrificial material, meaning the surface of the coating will come off over time. If you run your fingers over an acrylic coating, especially an older one, a substance that looks like powder will come off on your fingers. This continual shedding of the outer layer will eventually lead to the thinning of the coating over time. Every time it rains a little bit more of the acrylic coating will come off. For this reason, acrylic coatings are better for dryer climates.

- Buyer Beware: The lowest install bids tend to be paired with acrylic coatings due to its low cost. Additionally, please keep in mind that all coatings are only as good as the material you apply them to. They will not fix serious underlying problems.

Can I Mix and Match Coatings?

No, different coatings cannot be applied to the same roof. Each coating has its own bonding properties and are unlikely to adhere well to another layer of coating. This will also void any manufacturer’s warranty that comes with your coating. Any patching or repairs to an existing coating must be done with the same material.

Summary and Key Takeaways

- For most applications, we don’t recommend coatings as the best solution for most flat and low slope commercial roofs.

- However, there are a few limited circumstances in which coatings make sense and can be helpful in extending the life of your existing commercial roof.

- Thanks to silicone’s superior durability, it is quickly becoming the emerging leader in coating technology.

- There are no easy fixes! If your roof is leaking, or has other serious problems, spending the money to get it repaired the right way will save you money in the long run. Allowing water to continue damaging your building will cost more money in the future than the price of repairing your roof.