This article explores the long-term cost implications of both proactive and reactive maintenance using industry data and our own field experience.

To learn more about types of low slope roof damage and how they can affect your roof, check out the articles below.

-

- Commercial Failure Points: Installation | Materials | Drainage

- How to Prevent Your Commercial Roof from Failure Prematurely

We regularly see 20-year-old roofs with 5-year-old damage and new water stains on the ceiling. Damage timelines can vary wildly.

If water infiltration were a TV character, it would be the quiet one who says nothing for three seasons, then burns the house down during the Halloween episode.

Reactive Roof Maintenance: Definition and Common Causes

Fix it when it leaks.

Most businesses operate reactively by default, not necessarily by choice. Budget cycles, limited CapEx, staffing limitations, or different short-term priorities can preclude building owners or facility managers from proactive maintenance.

Most of us don’t top off coolant unless there’s a warning indicator. It’s easier to justify a solution for an existing problem than a theoretical one, and roofs are no different. A facility manager that takes a picture of myriad drop ceiling stains and sends it to the building owner with the text “We need a roof inspection” is more likely to elicit a response than one that sends “We need a roof inspection” with a photo of an unstained ceiling. If you have stains on your ceiling, you need a roof inspection. However, according to the NRCA, the most cost-effective time to inspect your roof is before it shows signs of damage, like leaks. And then every six months after that.

According to IFMA’s 2022 Europe Operations & Maintenance Benchmarks, nearly 90 percent of facilities used planned service contracts for HVAC systems, while only 58 percent of facilities proactively maintained their roof systems.

Ideally, facility managers aren’t presented with a zero-sum decision between proactively maintaining HVAC or their roof. Unfortunately, budget constraints often force them to choose which critical system to protect, and which one to watch like a hawk next time it rains.

Proactive Roof Maintenance: Planning and Process

Inspect and maintain regularly to prevent problems before they escalate.

Proactive roof maintenance is typically an element of a partnership that’s created collaboratively with the building owner or facility manager. For example, the maintenance plan can include resealing pitch pockets and termination bars, while more extensive repairs will be quoted. The price of a maintenance plan depends on myriad factors, including the building’s size, age, condition, height, and the building owner’s goals.

Every proactive maintenance plan shares one goal: catch minor damage before it becomes major. All proactive maintenance plans include regular inspections and fixes for potential issues, rather than current issues.

Commercial Roof Maintenance Cost Comparison: Reactive vs. Proactive

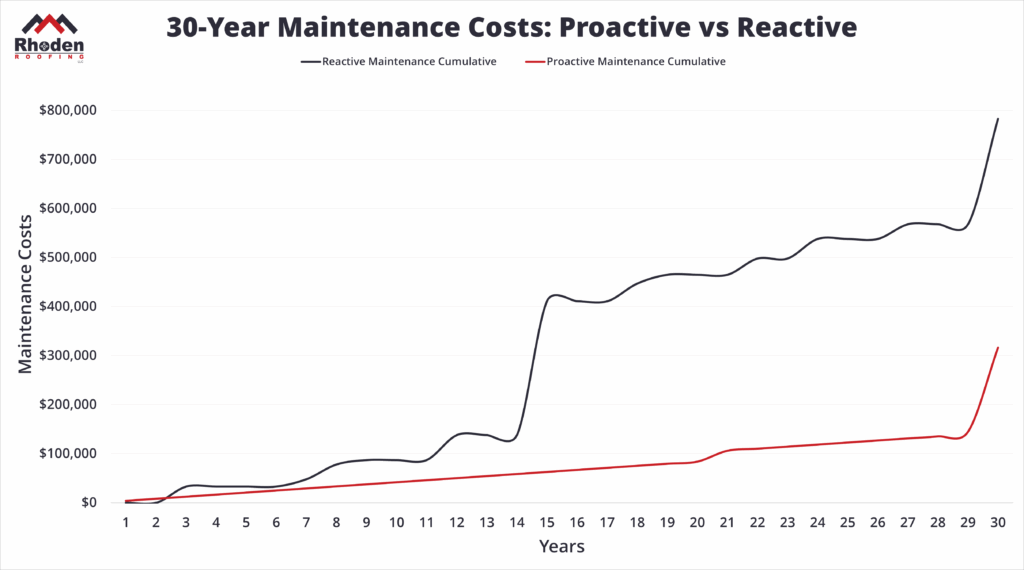

We created a model that weighs industry data, NRCA-data, case studies, and our experience in the field.

Our model echoes BOMA’s findings that reactive maintenance is 3-9 times more expensive than proactive maintenance. Proactive maintenance reduces cost per roof life cycle, cost per square foot, and aggregated 30-year costs. A longer lifespan also flattens the cost curve of a proactively maintained roof.

According to C.W. Griffin and Richard Fricklas in the “Manual of Low-Slope Roof Systems,” 40% of low-slope roofing problems originate from human error – foot traffic on the roof, HVAC incidents during HVAC repairs, faulty maintenance, or even improper installation. This damage commonly results in membrane tears, which can be addressed with a simple patch if water hasn’t permeated the substrate.

Once water gets in, problems escalate. Increased costs, operational disruption, and your roof’s lifespan will all be affected.

How Roof Leaks Disrupt Business Operations

Unplanned maintenance empirically causes substantial business interruption. We’ve seen instances of top floors losing viability, hotels closing premium rooms on the top floor, and tenants expressing frustration with building management over leaks.

A tenant’s bedroom in a multifamily residence that experienced catastrophic roof failure from unnoticed roof leaks.

A halt in operations has different implications for different businesses. A manufacturing facility could lose tens of thousands of dollars with an eight-hour pause in operations, while a financial institution might continue its regular operations while employees work from home. We’ve seen facilities intended for customer foot traffic, like gyms, that restrict access to equipment affected by leaks, resulting in equipment repairs and unhappy members.

While the building may remain functional, sometimes the risks of water-related damage, like mold, needs addressed before patrons are comfortable returning.

41% of people view odor resulting from moisture retention in buildings as a stronger deterrent to repeated visits than the presence airborne viruses, according to a GPS Air survey. Perceived “mustiness” or stale air can even erode brand reputation and result in poor reviews for hotel chains.

Even if your facility remains functional after interior leaks, it only takes one Google review with the word “damp” to damage a first impression.

Questions to Help Evaluate Your Roof Maintenance Needs:

-

- Can operations continue normally with an active leak in the facility?

- Have tenants or guests complained of a smell in the property before?

- Have I had to move employees, close rooms, or field tenant complaints due to water intrusion?

How Maintenance Strategy Affects Commercial Roof Lifespan

A newly installed TPO roof with semi-annual maintenance should comfortably boast a service life of 30 years. According to the NRCA, an unmaintained roof lasts between 10-14 years.

The NRCA cites a standard service life of up to 21 years for a maintained membrane roof. In our experience, a proactively maintained TPO roof can reach 28-30 years of service before a layover or replacement is necessary. After installing a roof system, we often warranty our installation for 30 years with a regular maintenance plan. This defers the need to replace or layover your roofing system by a dozen years, in some cases.

IFMA data found that a lack of maintenance procedures resulted in many building owners prematurely replacing their roofs, and it cited undetected moisture as the most common cause of premature roof failure. A probabilistic model published by Lounis et al. in 1998 continues to guide modern performance prediction frameworks: it shows that scheduled maintenance can halt the early onset of leaks that lead to unnecessary replacements. Both IFMA and Lounis’ model found the same thing: unnoticed damage adds up and, before you know it, your roof isn’t worth repairing.

A roof’s integrity can be quickly identified by answering the question “Is it capable of keeping water out?” For single-ply membrane roofs with existing substrate saturation, the answer to that question is “No.” And “no” is expensive.

Repairable damage like a membrane tear allows water into the insulation, and saturated insulation requires replacement. One membrane tear left untreated, let alone multiple membrane tears, will result in a roof system that can no longer be maintained: it needs replacement.

That’s why proactive maintenance can double a roof’s lifespan. Eventually the cost to repair a roof with severe water infiltration approaches the cost of replacement, and the roof is effectively totaled.

Questions to Help Evaluate Your Roof Maintenance Needs:

-

- Do I know when my current roof was installed?

- Am I budgeting for a re-roof in the next 5-10 years?

- When was the last time my roof was inspected?

Emergency Roof Repairs: Frequency and Prevention

A roofing emergency is damage that threatens people’s safety or the integrity of the property. An emergency repair is the solvent measure for these threats.

If we revisit our example of a membrane tear, an emergency repair would involve the application of a patch to the affected area after a leak is noted by the staff/tenants. With regular inspections, the damage is likely to be caught by the roof inspector, not the staff/tenants after substantial water infiltration has already occurred.

According to Khuncumchoo, a PhD recipient from the Georgia Institute of Technology’s College of Architecture, all low-slope roofs sampled in his 2007 dissertation (300+) experienced their first leak within 31-36 months of installation. A leak is a symptom, and the cause is water infiltration from the roof. Any unaddressed water infiltration can saturate the substrate, highlighting the importance of regular maintenance even in a roof’s infancy.

Emergency repairs are inevitable. It’s impossible to prevent a firework from landing on your roof, or 3” hail strikes, or a membrane tear resulting from an incident during routine HVAC maintenance.

After damage is caused, a timer is started. The longer the timer runs, the more expensive repairs are likely to be. An immediate repair for a membrane tear might require a $200 patch. After a year, water might saturate the substrate and ceiling, and tenant complaints will saturate email inboxes. Emergency repairs are frustrating, even without a $8,000 repair bill.

Proactive maintenance stops the timer. Often, this is enough to prevent emergency repairs from occurring. Reactive maintenance typically results in 4-7 emergency repairs per roof cycle, compared to approximately 0-1 with proactive maintenance.

BOMA’s preventive maintenance research findings suggest that emergency interventions cost up to nine times more than budgeted, regular proactive maintenance. The more emergency repairs that are required, the more costs can compound.

Most maintenance plans include sealant application, meaning vulnerabilities like exposed terminations or exposed nail heads are addressed during the inspection, before they become a source of leaks.

Example of proactive maintenance repairs.

Top-fastened, aged coping caps were beginning to fail. To extend its service life, the coping caps were cleaned and coated to maintain resistance to water infiltration, preempting a potential leak.

Gab in Drip Edge Metal

Sealant Applied to Drip Edge Gap

Example of proactive maintenance repairs.

The drip edge adjacent to the commercial box gutters had separated, creating an entry point for water.

In the left image, a probing tool is used to illustrate the size of the gap, which is approximately the diameter of a pencil.

Sealant was used to maintain waterproofing integrity, although the potential vulnerability will be re-assessed at the next inspection.

Acute damage from wind-blown debris, foot traffic, or hail are still possible between scheduled maintenance. These can still require emergency repairs if not promptly treated.

There’s a reason insurance companies designate hail and tornados as “acts of God.” For commercial low-slope roofs, a high-quality cover board and a fleece-backed membrane can mitigate damage from hail, but hail and tornados can’t be prevented altogether.

Questions to Help Evaluate Your Roof Maintenance Needs:

-

- How many emergency repairs have I paid for in the last five years?

- When was the last hailstorm my building experienced?

- Could my current maintenance budget absorb an $8,000 emergency roof repair?

When Is Reactive Roof Maintenance the Right Call?

If reducing long-term aggregated expenses is the only goal, proactive maintenance is the obvious choice. Then why doesn’t every facility manager have a maintenance plan? Because if reduced expenses are the only priority, loans with interest wouldn’t exist. Yet, millions of loans are taken out each year. Similarly, facility managers are balancing aging infrastructure, short-term leases, staffing limitations, uncertain capital availability, and more. That’s why a successful maintenance strategy is tailored, not only to the building, but to the business that operates in it. The needs of a multi-tenant retail space differ from the needs of an 80,000-square-foot warehouse.

Sometimes, a roof in disrepair simply can’t be maintained. Before entering maintenance partnerships with facility managers and building owners, we assess the condition of the roof to 1) approximate its remaining service life, 2) identify any deferred maintenance and propose solutions to outstanding issues, and 3) determine whether the roof can be effectively maintained. A roof with widespread membrane failure and degraded metals is a candidate for replacement, not preventive maintenance.

Finding the right partner for a maintenance strategy is just as important as the strategy itself. Some businesses are comfortable handling repairs on their own, while others have been burned by contractors in the past. Every building’s needs are different. So are the people managing them. The best maintenance plan is the one that works for both.

Questions to Help Evaluate Your Roof Maintenance Needs:

-

- What are the constraints keeping me from a proactive roof maintenance plan?

- If nothing changes, what would I expect to spend on my roof over the next decade?