Last updated: June 2025

Single-ply membrane roofs (TPO, PVC, and EPDM) are typically fastened to commercial buildings in one of two ways: mechanically attached or fully adhered. There are other methods but these two are by far are the most common. Note that self-adhesive roofing, like peel-and-stick self-adhesive bitumen, are considered fully-adhered, but for the purpose of this article we are only comparing applications of singly-ply membrane materials that offer a choice of installation method. Virtually all flat (in the industry, called “low-slope”) roof membranes sit on top of a layer of insulation or cover board that rests between the membrane above and the structural roof deck below.

Summary – Quick Comparison: Mechanically Attached vs Fully Adhered

Which is Better For Your Application? Mechanically Attached or Fully Adhered Roof Systems?

The roof system you select will likely be determined by your budget, roof design, and the job your roof needs to perform. Here are the primary considerations building owners/managers typically use when making a decision, as well as the most common “surprises” about each system that we hear about from customers that they wish they knew ahead of time

- Durability: Fully adhered roof systems tend to last longer, but are more difficult to repair than a mechanically attached roof system.

- Cost: Fully adhered systems are typically 10-20% more expensive to install, based on additional install labor required as well as adhesives cost more per area covered than mechanical anchors and fasteners

- Wind Uplift & Sound: Mechanically attached membranes move, or flutter, in the negative air pocket created over buildings in the wind. Depending on deck system and insulation, this fluttering can be heard within the building when it is windy, disrupting office or residential spaces. Membrane movement (fluttering) of mechanically attached membranes mean slightly more wear over time and a shorter life expectancy, especially on tall buildings or areas with high wind exposure. Where sound attenuation is important on a mechanically attached roof, 6-foot width membrane rolls can be used as opposed to standard 10-foot widths. Thicker membranes (e.g. a 60-mil TPO instead of a 40-mil) will also have less movement.

- Puncture Resistance: Mechanically attached membranes have less puncture resistance than fully adhered systems, relevant if the roof expects a lot of foot traffic or service work (e.g. to HVAC units)

- Concrete Decks: Roof systems with concrete decks are almost always fully adhered. While mechanical attachment is possible, the labor costs to pre-drill every anchor point into concrete get rid of any cost savings associated with mechanical attachment

- Cost Scalability: In our experience, mechanically attached roofs are more common on large roofs. Installation efficiency (i.e. actual hours of installing roof labor relative to hours of preparation) goes up on large-scale installs, making the labor savings more meaningful. Additionally, the proportion of adhesive costs (at $200-400 per bucket) relative to the total build cost are more noticeable at scale. Finally, the cash flow impact of a roof replacement for a large building may simply be more than a business can sustain at one time, making cost the most important variable.

- Fumes & VOCs: Fully adhered roofs produce volatile organic compounds (VOCs), and much more noticeably, smells, during install and for 24-48 hours afterward as the adhesive cures. Depending on the project, these VOCs can be a nuisance around areas of occupancy, like the front door of a retail store or at an office building. We have performed roofing projects during summer break at schools to avoid fumes impact, or for smaller jobs, suggest scheduling late in the week to allow a few days over the weekend while people are out of the building. Note that mechanically attached low slope roof systems also use adhesives (at curbs, penetrations, and parapet walls), but in much smaller quantities than a fully adhered roof. VOCs are not often a concern when installing a mechanically attached roof.

- Installation Temperature: Adhesives are temperature-dependent. Manufacturer specifications vary, but typically daytime temperatures have to sustain over 45 degrees Fahrenheit during installation. In our region in the lower Midwest, this is more relevant to larger buildings, where work takes more than a month. Roofing projects against a deadline, such as a building sale, may have to use mechanical attachment if the installation is in the winter.

Routine Inspection and Maintenance

Mechanically Attached and Fully Adhered both require proactive preventative maintenance programs to prevent hazards from becoming leaks and to prolong the life of the membrane. Most manufacturers require a routine inspection or maintenance program to keep the warranty in good standing. Rhoden Roofing offers a preventative maintenance program called RoofCare. RoofCare is designed to save building owners money, increase the lifespan of the membrane, and reduce headaches that come from unexpected & preventable leaks by doing proactive maintenance twice per year.

How to Identify Which Roof System Type On a Commercial Building:

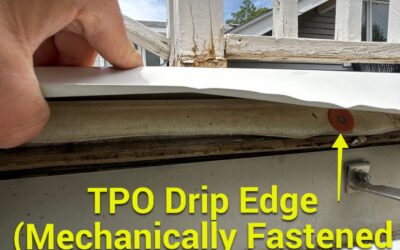

Identifying Fastener Type

Fully adhered roofs are smooth, whereas fasteners on a mechanically-attached system will be visible as a grid of cleat fasteners across the roof surface.

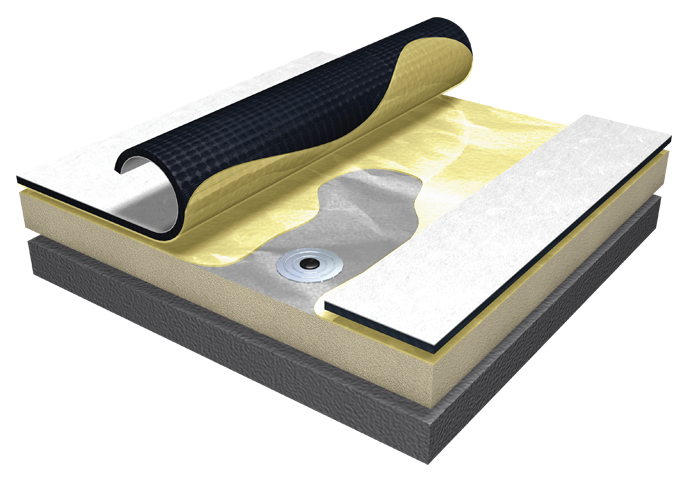

Fully Adhered Illustration

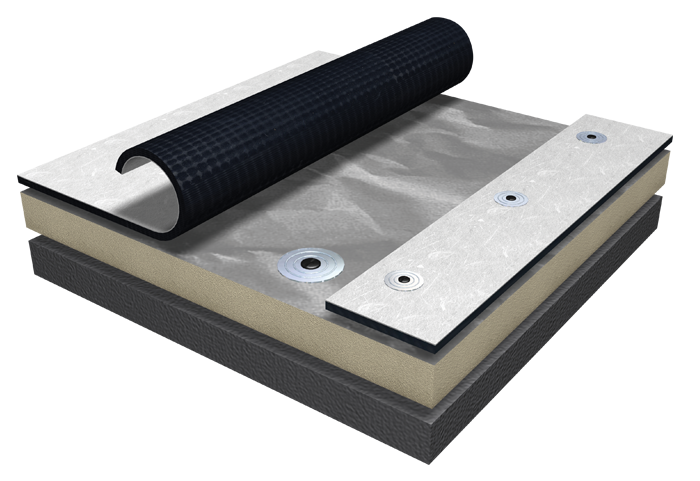

Mechanically Attached Illustration

Identifying Membrane Type

While there are other types of membrane roof systems, these are the most common.

- TPO membrane is usually white, or light colored. However, because TPO can be used as a ballasted roof, it may be covered in gravel.

- EPDM is dark in color (usually black or dark gray), and similar in texture to a tire inner tube. EPDM can also be ballasted, so it may also appear gray with gravel on top.

- PVC low slope roofing membrane is usually white, gray, or light brown in color. PVC, like TPO and EPDM can be ballasted, so it may be below gravel as well

- ModBit or Modified Self-Adhesive Bitumen is made from fiberglass and polyester materials to create a reinforced mat, usually embedded with small granules. It is typically installed in 3-foot wide rolls rather than 10-foot, and looks more like an asphalt roof shingle found in residential applications.

This article is part of our ‘Low Slope and Commercial Materials’ Series. Learn more about:

System Types and Surface Materials

- TPO vs EPDM

- TPO vs PVC

- Mechanically Attached vs Fully Adhered Roofing Systems

- Black Roofs vs White Roofs

- Is a Metal Roof Right for My Commercial Property?

- Can a Commercial Roof Coating Save Me Money

- 3 Best Commercial Roofs in Wichita, KS

Substrate Systems

- Polyiso Insulation vs EPS Insulation

- What Do I Need to Know About Tapered Roofing Insulation Panels?

Inspection & Maintenance

Miscellaneous