Box vents, often called turtle vents because of their shape, are the most common type of exhaust vent on residential roofs. They are louvered vents that allow hot, humid air to escape the attic, contributing to balanced ventilation in a passively ventilated attic space.

As air in the attic warms, it rises and exits through vents located near the top of the roof, usually the ridge. That warm, exhausted air is then replaced by cooler air drawn in through intake vents near or at the bottom of the roof, usually soffit vents. Balanced ventilation refers to this phenomenon: warm, moist air escaping through exhaust vents before it condenses on roof decking and then replaced by cooler air from below.

Box vents are considered static exhaust vents. They do not move or contain a motor, which makes them inexpensive, easy to install, and ubiquitous as a result.

For more information on the importance of balanced attic ventilation, see Why Is Proper Attic Ventilation So Important.

An asphalt shingle roof that retained box vents when the roof was replaced due to its complex attic structure with insufficient continuous ridge length for ridge vent, our preferred form of exhaust ventilation. In situations like this, box vents provide code-compliant ventilation where ridge vent would be insufficient.

See our article Continuous Venting Ridge vs. Static Box Vents: Which Is Better? to compare exhaust ventilation options.

Expected Service Life of Box Vents

Box vents typically last 15-25 years, or near the service life of the roof itself.

The aluminum vent housing itself often outlasts the fasteners that secure it and the sealant that mitigates water infiltration. Because most roofs with box vents feature four or more of them to sate ventilation requirements, they often wear at different rates.

As with most other roofing components, some circumstances can contribute to accelerated wear of box vents:

- Proximity to overhanging tree branches

- Proximity to valleys or a roof slope that channels large volumes of water runoff

- Extensive exposure to UV radiation, such as those on unobstructed south-facing slopes or in new neighborhoods without adult trees

As a result, some box vents on a roof may last for 25 years, while others may require repairs after 10-15 years.

Evaluating & Addressing Box Vent Condition at Different Lifecycle Stages

0-5 Years: New Installation – Evaluating for Correct Installation

After a box vent is installed, evaluation primarily comprises inspecting for correct installation.

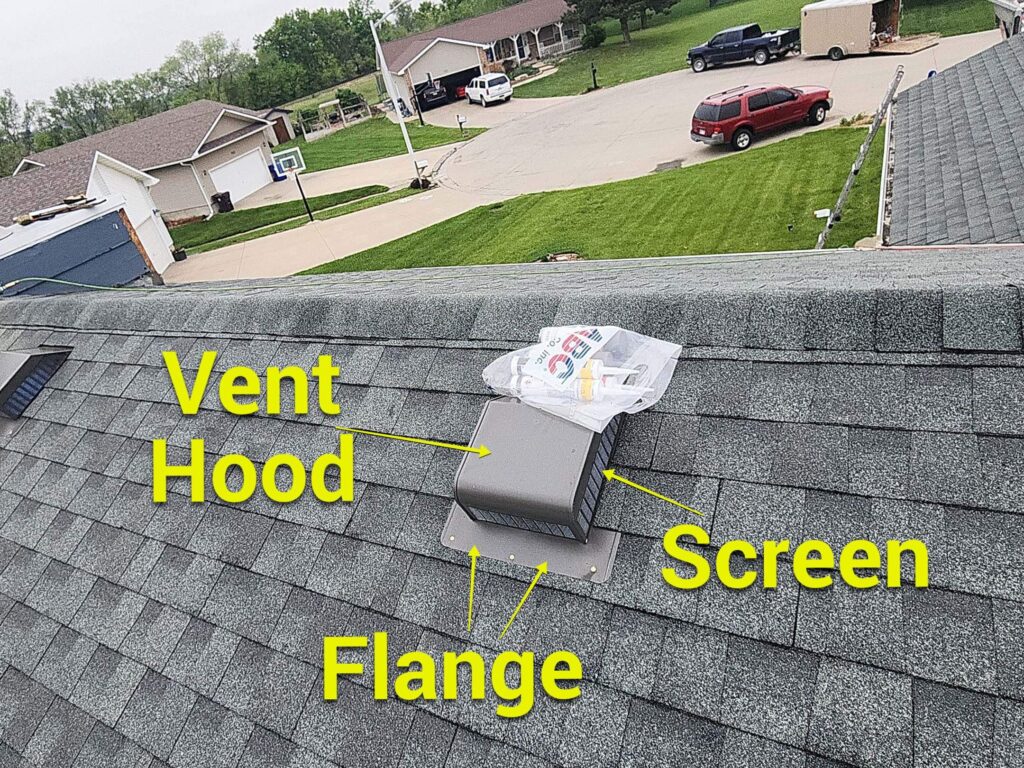

See How to Replace a Damaged Box Vent On a Roof to learn more about proper box vent installation.

- Exposed Nail Heads or Loose Nails: Exposed fasteners on the downslope side of the flashing invite leaks. They must be sealed with UV-resistant caulk or replaced if backing out.

- Mixed exhaust methods: Air should have a single exhaust method from the attic at or near the apex of the roof. Mixing exhaust methods (e.g., ridge vent paired with box vents lower on the roof for a single attic space) risks short-circuiting the ventilation system, no different from drinking through a straw with a hole in the middle: some air will make it to the end (near the ridge), but most of it will escape through the hole (lower on the roof).

- Improper shingle overlap: The up-slope portion of the box vent’s flange should be overlapped by shingles. On either side of the vent, shingles should not overlap the vent housing, as that can allow water to pool and eventually enter.

- Vent installed too low: All exhaust vents must be placed as high on the roof as possible. This minimizes dead zones in the attic space where no airflow occurs. A box vent installed in the middle of a slope, for example, is installed too low. They should be installed as close to the ridge as possible.

- Vent installed over structural member: To maintain a uniform appearance from the home’s exterior, some contractors may install a box vent over a structural member, like a rafter or truss. While this isn’t an inherent problem, as some air will continue to exhaust from the vent, it does reduce the available NFA, or the vent’s effectiveness. If the contractor did not account for this, the attic may have unbalanced ventilation.

5-15 Years: Normal Weathering – What to Monitor

Once a box vent has been exposed to the elements for several years, inspections begin monitoring continued signs of aging. Most changes at this stage are cosmetic or maintenance-related rather than signs of failure.

- Hairline cracking or drying sealant: The UV-resistant sealant protecting the fasteners may begin to dry and produce minor hairline cracks.

- Surface discoloration from UV exposure: Subtle discoloration from UV exposure can appear on a box vent, especially if it’s painted. It’s the roofing equivalent of sun-bleached patio furniture: still functional, just lighter in color.

- Minor surface rust: Metal vent housing may develop staining, either as white mineral deposits from coating breakdowns or as small patches of reddish-brown oxidation – an early sign of rust.

- Small dents on vent housing: Small indents from hail, tree limb abrasions, or incidental damage are common after a few years. These can occur on both the vent housing and exposed metal flange.

Maintenance: Reapply sealant.

Because box vents are static with durable housing, they typically perform well over the first 10-15 years of service life with minimal maintenance. Degraded sealant, especially for box vents on south-facing slopes, should be reapplied where fasteners are exposed on the downslope side of the flange. All other signs of normal weathering are cosmetic.

This box vent exhibits multiple signs of failure and one sign of improper installation. Repeated, heavy hail impacts have severely deformed the metal vent hood and created multiple perforations, both of which require replacement. This roof system does not require a box vent for attic ventilation at all, since the ridge vent pictured on the left offers adequate exhaust. Combining ridge vent and box vents, two separate forms of exhaust, is only appropriate in one situation: when a box-style termination is used exclusively for a dedicated exhaust fan, such as a bathroom fan or stove vent hood. Even then, a baffled fan termination, such as a Broan vent, is preferred.

15-25 Years: Failure & Replacement – Knowing When It’s Time

The functional life cycle of a roof component is determined by its ability to keep water out. The transition from normal aging to concerning wear isn’t always clear. To clarify what these thresholds are, we created an inspection checklist to standardize our recommendations, ensuring that suggested only when it’s necessary. Similar to how an insurance adjuster defines “totaled” on a car, we only recommend component replacement when the cost to replace a component or roof is less than the expected cost of damages over the next 12 months.

Based on our experience identifying and fixing roof leaks on over 13,000 homes and buildings, here are our criteria for when we recommend replacement of box vents:

- Warped or deformed flange that no longer sits flush against the roof: Deformation compromises the metal’s ability to seal and allows water to migrate under the flashing

- Corroded metal deterioration with active pitting rust or rust located where sealant is applied. Pitting rust compromises the material and makes it ineffective at its job: to keep water out. Rust located where sealant is applied near fasteners will prevent the sealant from adhering altogether.

- Water intrusion: If moisture has already found its way through the flashing and into the interior, the flashing needs replaced. Interior leaks will be visible as discoloration to surrounding wood or insulation, grime lines or staining on the flue itself within the attic, mold, or wet spots on drywall or sheetrock below.

- Abrasive damage or cracks that are more than half the thickness of the material: More common with plastic box vents than aluminum box vents, any damage or cracks that compromise the material create entry points for water. This is especially dangerous if it occurs on the upslope side of the vent, where water runs over the vent.

This article is part of our ‘Roof Component Inspection & Service Life’ Series. Learn more about:

Flashing

Roof Vents