What Are Gutters & Downspouts and What Do They Do?

Gutters collect rainwater that flows from the roof and directs it to downspouts, which carry runoff safely away from the home. Together, they form the drainage system that protects roofs, siding, and foundations from extended water exposure. Because nearly every sloped roof includes gutters and downspouts, they’re among the most common components for modern roof systems.

Most residential gutters and downspouts are made from roll-formed aluminum and affixed to fascia on the eaves of a house. Aluminum balances light weight, corrosion resistance, and cost efficiency, which is why it’s preferred by most contractors. Steel and copper options exist, but aluminum is by far the most common gutter material used for modern homes: It’s malleable enough to shape on site, strong enough to resist most abrasive impacts, and can be painted to match the home.

Gutters that measure 5” from the outer to inner edge are most common, though 6” systems are increasingly common on steep or smoother specialty roof materials (e.g., tile or metal) that shed large volumes of water. To understand how size affects drainage capacity, design, and cost, read our guide on 5-inch vs 6-inch gutters.

Downspouts are typically 2” x 3” but can also be upsized to 3” x 4” when they’re likely to channel large volumes of water or debris.

Expected Service Life of Gutters & Downspouts

Aluminum gutters and downspouts have a typical lifespan of up to 20 years, with proper maintenance. Theoretically, downspouts can outlast gutters, although we recommend replacing both simultaneously to ensure your drainage system works as intended.

0-5 Years: New Installation – Evaluating for Correct Installation

The installation issues cited below will cause gutters to sag, pull away from the fascia, overflow with water, and split at the seams. However, these issues can take years to manifest. By the time these issues develop, the foundation or fascia boards may already be affected. When assessing new gutter and downspout installations, we look for the following issues.

- Insufficient Slope: Gutters require a minimum slope of ~1/4” per 10’ toward downspouts. Inadequate slope causes pooling water and overflow – two symptoms of ineffective gutter systems.

- Gutters Fastened into Rotted Fascia: Just as roofs require solid decking to hold nails, gutters require solid fascia to hold fasteners. When fascia boards rot, the fasteners lose grip, causing gutters to sag or detach.

- Gutter Spikes: Over time, gutter spikes begin to pull out from the fascia board. Friction between the spike and the fascia board keeps it in place, but thermal expansion and water weight will gradually pull the spikes out. While they offer acceptable performance, they are very likely to cause premature gutter failure.

- Over-Spaced Spacers: Gutters need proper support to prevent sagging. A belt with two loops is going to sag, and gutters are no different: for proper securement, gutters require hangars to be spaced approximately 18”-24” apart in areas with heavy rainfall or snow accumulation, like Kansas. In areas without regular precipitation or freeze cycles, hangers can be fastened up to 36” apart, although we recommend spacing of no more than 24”.

- Excessive Seams: If a 40 LF run of gutters has three, four, or five seams, then it’s three, four, or five times more likely to leak. Failed seams are among the most common causes of gutter leaks. The more seams on a gutter system, the more likely it is to leak. We always recommend seamless gutters to minimize the risk of leaks, where the only seam is at elbow joints.

- Gaps Between Gutter and Fascia: Gutters should sit flush against the fascia board they’re mounted to. Any noticeable space – visible daylight behind the gutter or if a finger can fit between the gutter and fascia – indicates improper mounting. Small gaps allow water to miss the gutter when it runs off the roof, leading to rotted fascia.

- Incorrect Gutter Size: A roof’s steepness directly affects how much water its gutters need to handle. For example, a 10:12 roof has about 24 percent more surface area than a 4:12 roof of the same footprint. That extra runoff accelerates more quickly toward the gutters, which can cause 5” gutters to overflow and sag. 5” gutters can hold 1.2 gallons per foot, while 6” gutters hold roughly 2 gallons per foot. For roofs with a 7:12 pitch or greater, that additional inch of width may be necessary.

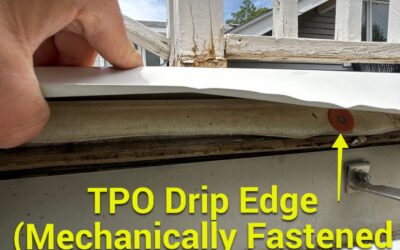

- Hangers Fastened Through Drip Edge: Drip edge is the metal flashing that runs along the edge of the roof. It guides water runoff into the gutters, protecting the fascia beneath from water exposure. If hangers are fastened through the drip edge, runoff may enter through the puncture, causing it to saturate roof decking or fascia.

A small gap is visible between the fascia and gutters, a sign of improper installation.

Gutter spikes are much more likely to fail prematurely than hidden hangers, which are the standard for modern gutter installations.

2-10 Years: Normal Weathering – What to Monitor

Over time, gutters and downspouts experience small, predictable changes from existing outside in the elements. Sunlight will begin to dry sealant, temperature swings cause metal to expand and contract, and paint will fade. These issues are mostly cosmetic, similar to the sole of a shoe wearing out from daily use.

- Space between downspout sections: Downspout sections are typically screwed or rivetted together at the top and bottom miter joints (or elbow joints). These fasteners can begin to pull out due to thermal expansion and repeated water impacts, creating space between downspout sections. As long as water is channeled out through the bottom of the downspout, this is not typically an issue.

- Minor Hairline Cracks on Drying Sealant: The UV-resistant sealant holding elbow joints may begin to dry up and produce minor hairline cracks. Small, superficial cracks in sealant like this don’t require immediate attention, but they should be monitored to preempt its eventual deterioration.

- Surface Discoloration: Painted aluminum will naturally dull over time from UV radiation, producing color changes and potential streaking.

- Loosened Fasteners: Thermal expansion and the vibration produced by water draining into the gutters can cause fasteners to loosen. This will occur rapidly with gutter spikes, often between 2-5 years after installation. Hidden hangar systems remain secure for longer. To learn more about the difference between gutter fastening systems and how they’re addressed, see our guide to replacing gutter clips.

- Debris Buildup: Twigs, leaves, acorns, or other nesting materials can collect in both gutters and downspouts, slowing or preventing drainage.

Maintenance: Clear debris, tighten fasteners, and paint. Debris should be cleared from gutters and downspouts, if necessary, on a semiannual basis. Homes surrounded by tall trees may require cleaning up to four times a year to prevent clogs.

Typically, loose fasteners on hidden hanger systems can simply be tightened. Backed out fasteners that are no longer fastened may require more extensive repairs to address what caused them to back out in the first place. Repainting is an optional cosmetic enhancement that does not affect the drainage system’s performance.

10-20 Years: Developing Signs of Aging – Proactive Care Recommendations

Cosmetic wear eventually gives way to material fatigue. UV radiation, thermal expansion, and years of water flow can cause fasteners to back out and sealant to dry up.

Fasteners securing downspout sections – elbow joints adjoining with the vertical run of downspout, for example – are typically zinc-plated or otherwise coated to resist corrosion. Over time, the coating can degrade and the screw will begin to rust. While the downspout’s paint in the photo above is worn, the section is still structurally sound and draining properly. Replacing the rusted fasteners with new, coated screws ensures that the elbow joint remains secure and all runoff drains to the downspout’s opening on the ground.

- Sagging Gutter Sections: Visibly sagging gutters always produces ponding water and slower drainage.

- Degraded Sealant or Joint Separation: The most obvious way to identify this is by noting rapid dripping or water streaming from joints or any seam in the gutter. If the rain and drippage stop at roughly the same time, it’s likely a result of degraded sealant or joint separation. If the rain stops and the dripping continues, it’s likely a result of ponding water and some amount of sealant degradation.

- Backed Out Fasteners: There are many reasons that fasteners may completely back out. Many of these reasons, such as rotted fascia or excessive weight from debris or snow pulling the fasteners out, require the hangar to be relocated or repairs to the damaged fascia.

- Rusted Fasteners: Fasteners on downspout faces or gutter hangers can develop surface rust over time as their coating wears off.

- Loose or Detached Downspout Mounting Strap: Downspouts are secured to the home with metal mounting straps that fasten to the siding or masonry. Over time, thermal expansion may cause these straps or their screws to loosen, allowing the downspout to pull away from the wall. This can cause the joint connecting it to the gutter to flex as wind or flowing water moves the now-loosened downspout. If the downspout wobbles when horizontal pressure is applied, failed mounting straps are often responsible.

Maintenance: Tightening and Resealing. UV-resistant sealant needs reapplied in areas where sealant has degraded. Any loose hangars or downspout mounting straps can be re-fastened. Isolated sections of sagging gutters can often be leveled by tightening any loose screws, provided the fascia is intact. Similarly, rusted fasteners can simply be replaced if the surrounding metal is intact.

When the opening of a downspout is crushed, water loses its only clear path out. Because water can’t be compressed, it builds pressure against the crushed opening until it finds an escape elsewhere, often through seams higher up. That strain not only forces water to channel through unintended areas but can also cause joint separation over time. Severely deformed metal like this can’t be reshaped, so crushed sections must be replaced.

15-20+ Years: Failure & Replacement – Knowing When It’s Time

The functional life cycle of a roof component is determined by its ability to keep water out. The transition from normal aging to concerning wear isn’t always clear. To clarify what these thresholds are, we created an inspection checklist to standardize our recommendations, ensuring that any suggested work is necessary. Similar to how an insurance adjuster defines “totaled” on a car, we only recommend component replacement when the cost to replace a component or roof is less than the expected cost of damages over the next 12 months.

Gutters and downspouts aren’t on the roof, but they are essential to the roof system’s function of keeping water out. When they fail, water the roof sheds can be redirected into soffits, fascia, or the foundation. The roof may be performing well, but the system designed to keep water out of the house has failed. We evaluate gutter and downspout condition in the same inspection because their performance is integral to the roof’s job of keeping water out.

Based on our experience identifying and fixing roof leaks on over 13,000 homes and buildings, here are our criteria for when we recommend replacement of gutter and downspout materials:

- Corroded metal deterioration with active pitting rust or rust. Pitting rust compromises the material and makes it ineffective at its job: to keep water out. Rusted through and perforated downspouts can even allow water behind siding.

- Cracks that are more than half the thickness of the material – such as from a branch falling, hail impact, or maintenance error.

- Widespread and Chronic Overflow: Overflowing gutters can be caused by a number of issues, from improperly sloped gutters to debris obstruction. If the issue affects multiple slopes and occurs frequently during rain, the gutters are likely undersized, fastened to rotting fascia that prevents the gutters from remaining taut to the eaves, or secured improperly.

- Deformed Gutter Sections: When gutter runs or corners are excessively bent, they are likely to exceed the metal’s elastic limit, similar to a piece of paper that can’t be properly “unfolded” back to its original stiffness. This prevents the gutter from draining properly and requires replacement.

- Crushed or Deformed Downspout Sections: Downspouts are most likely to deform at 1) the ground, where the downspout discharges runoff, or 2) at the elbows, where they redirect water flow. Even modest dents reduce the available area for water to flow and increase the chance for sediment or leaves to lodge. Larger crushed sections significantly increase the likelihood of clogging and unintended water discharge higher on the downspout. Any damage that obstructs water flow or prevents a secure joint requires replacement, since these deformations permanently affect the metal.

This article is part of our ‘Roof Component Inspection & Service Life’ Series. Learn more about:

Roof Covering

Flashing

Roof Vents

Roof Drainage