What Is Counterflashing and What Does It Do?

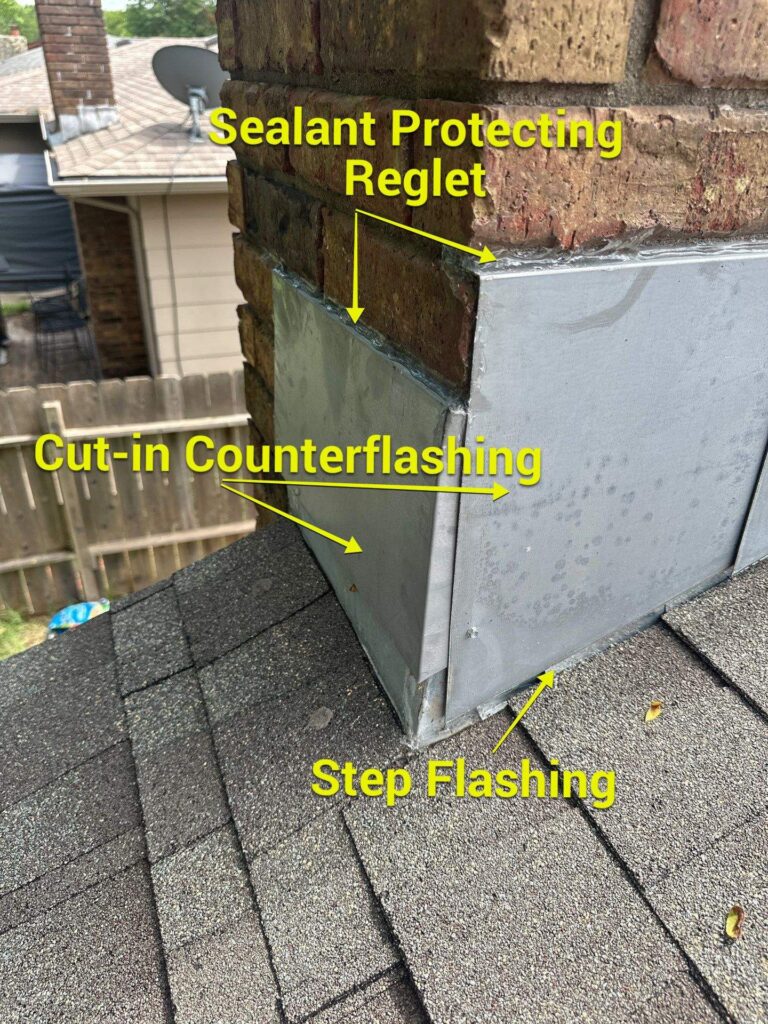

Counterflashing is an upside-down L-shaped metal piece that protects roof-to-wall transitions, like you would find on a brick chimney. Step flashing protects the roof-to-wall intersection, while counterflashing covers the step flashing to prevent water from sneaking behind it.

Think of it like tucking your shirt into your pants, then pulling a rain jacket over the top. The tucked shirt is secure, but the jacket keeps wind and rain from entering around its edges. Similarly, counterflashing locks water out by overlapping the step flashing and directing runoff safely onto the roof’s surface.

There are two types of counterflashing:

-

- Cut-In Counterflashing: This flashing is embedded directly into the wall, usually into masonry joints or brick mortar. The top flange of the metal sits inside of the wall and is secured with sealant. Water hitting the wall runs over the flashing and onto the roof while minimally contacting the step flashing.

- Surface-Mounted Counterflashing: This flashing sits on the surface of the wall, attached with fasteners. It’s easier to install and better-suited for homes with fragile stucco siding. Sealant is applied at its top edge to keep water out. This sealant is its primary waterproofing measure, not a redundancy like it is with cut-in counterflashing.

Neither type of counterflashing is necessary on a house with wood or vinyl siding, since the siding protects the step flashing from water infiltration at its top edge.

Expected Service Life of Counterflashing

While manufacturing material and quality vary, most counterflashings are made with the expectation that they can last the lifespan of the field shingles on the roof itself. A 20 or 30-year service life for counterflashing is reasonably common. This assumes that counterflashing was replaced during the last roof replacement, which is not always the case. Because step flashing beneath the counterflashing is often reused by discount roofers, there’s little reason for them to replace the existing counterflashing, even though replacing both is best practice.

Evaluating Counterflashing Condition at Each Lifecycle Stage

0-5 Years: New Installation – Evaluating for Correct Installation

Counterflashings are usually aluminum or steel. You can find out by using a magnet to see if the material is ferrous – magnets stick to steel, but not aluminum. Within the first few years of installation, counterflashing should still look clean and uniform, taut to the vertical surface with unpitted metals, healthy sealant, and minimal surface discoloration on painted bonderized or anodized metals. Some common errors we see with counterflashing installations that you can look for are:

-

- Surface-Mounted Counterflashing: When possible, sealant should be a redundancy, not the primary method of waterproofing. Surface-mounted counterflashing relies on sealant to keep water from running behind it. In situations where stucco or old masonry might crack or chip when a reglet is cut, or on roofs with highly irregular geometry, surface-mounted counterflashing may be necessary. It just requires more regular resealing to ensure that the main method of waterproofing, sealant, remains effective.

- Exposed Nail Heads or Loose Nails: Cut-in counterflashing isn’t always face-fastened, so it doesn’t always have visible nail heads. Surface-mounted counterflashing is generally face-fastened, meaning a screw will insert through the exterior of the metal flashing and into the wall to secure it. The fastener is inserted off the roofline at the vertical portion of the wall, so water is unlikely to infiltrate at the fastener. Sealant is often used as a redundancy here, although it’s not required.

- Re-used Counterflashing Older Than the Roof: If you can see two sets of nail holes on surface-mounted counterflashing – former nail holes that have been sealed (hopefully) but no longer have nails in them, it’s a sign that flashings were reused when the roof was last replaced. Counterflashings that appear worn compared to newer components (e.g., oxidation or mild bending from manipulation during shingle installation) suggest that any step flashing underneath was reused as well. Multiple types of visible sealant atop the counterflashing are a sign that the flashing was reused, as the area is cleaned and old sealant removed before installing new flashings.

- Mismatched Metals: While uncommon, using a different metal for counterflashing than was used for step flashing can result in galvanic corrosion. Mismatched metals can be the result of haphazard repairs or material shortages, and it will discolor metals where they meet, like at the bottom of the counterflashing where it contacts step flashing. Even when both metals are coated, steel and aluminum can begin to corrode when used together on a roof as water contacts the metals.

- Surface-Mounted Counterflashing: When possible, sealant should be a redundancy, not the primary method of waterproofing. Surface-mounted counterflashing relies on sealant to keep water from running behind it. In situations where stucco or old masonry might crack or chip when a reglet is cut, or on roofs with highly irregular geometry, surface-mounted counterflashing may be necessary. It just requires more regular resealing to ensure that the main method of waterproofing, sealant, remains effective.

5-20 Years: Normal Weathering – What to Monitor

Counterflashing is likely to discolor as it ages. Unless the discoloration is a result of severe oxidation, it’s purely cosmetic. With prolonged exposure to the sun/UV radiation, signs of age will show up on counterflashing. Each counterflashing material weathers differently. The typical signs of aging for step flashing are:

-

- Minor Cracks in Sealant: The UV-resistant sealant atop the counterflashing, where it intersects with the wall, may begin to dry up and produce small cracks. Sealant is a redundancy for cut-in counterflashing, but it’s critical to surface-mounted counterflashing’s performance. Without it, water can run behind the counterflashing and step flashing, producing a leak.

Aluminum Step Flashings

-

- Develops mild surface cracking on powder-coated color finish.

- Texture may lighten as coating wears.

- Coated aluminum fades over time.

- More susceptible to cosmetic marring (e.g., dents and mild wrinkling) from storms or incidental contact from siding or masonry repairs.

Steel Step Flashings

-

- Heavier and more rigid, so they retain their shape better.

- More prone to oxidation and rust if the coating is abrased.

Galvanized Step Flashings

-

- May begin showing white mineral staining as the zing coating wears off.

- Can develop darker staining where scratched by branches or other wear.

Maintenance: Sealant reapplication or cleaning. For counterflashing in its first few years, maintenance is generally minimal. Cut-in counterflashing relies primarily on its reglet for waterproofing so minor cracks in sealant over the top are not critical, although reapplying sealant can preempt any potential leaks. Surface-mounted counterflashing, on the other hand, depends on the sealant to keep water from running behind it and the step flashing. All cracks or gaps should be resealed with UV-resistant caulk. Cleaning is optional for both installation methods. Restoring its appearance with a light cleaning solution may help spot early wear, but it will not directly extend its service life.

Surface-mounted counterflashing on a stone chimney. As sealant degrades from UV exposure, regular reapplication is required for surface-mounted counterflashing. The black material above and below the flashing here is caulk from previous applications. Caulk at the base of counterflashing is unusual, and it suggests that leaks have been sourced to the chimney previously.

20-40+ Years: Failure & Replacement – Knowing When It’s Time

The functional life cycle of a roof component is determined by its ability to keep water out. The transition from normal aging to concerning wear isn’t always clear. To clarify what these thresholds are, we created an inspection checklist to standardize our recommendations, ensuring that suggested only when it’s necessary. Similar to how an insurance adjuster defines “totaled” on a car, we only recommend component replacement when the cost to replace a component or roof is less than the expected cost of damages over the next 12 months.

Flashing is an interconnected system, so counterflashing replacement is not a simple swap. The wall must be cleaned to remove old sealant from previous touch-ups, ensuring a tight seal for the new flashing. Next, nearby shingles will need lifted if the step flashing beneath needs replaced to maintain the system’s integrity. New reglets in the masonry may need to be cut to secure the replacement counterflashing properly. Replacing counterflashing can be a significant repair. Based on our experience identifying and fixing roof leaks on over 13,000 homes and buildings, here are our criteria for when we recommend replacement of counterflashing:

- Corroded metal deterioration with active pitting rust or rust. Pitting rust compromises the material and makes it ineffective at its job: to keep water out.

- Abrasive damage or cracks that are more than half the thickness of the material – such as from a branch falling, hail impact, or maintenance error.

- Water intrusion – If moisture has already found its way through the flashing and into the interior, it needs replaced. Resealing counterflashing that has already allowed water infiltration traps the moisture, preventing it from drying. Interior leaks will be visible as discoloration to surrounding wood or insulation, grime lines or staining on the wall itself or wet spots on drywall or sheetrock below.

- Warped Flashing: Metal flashing has warped, preventing a tight seal to the wall and/or weaking the metal’s integrity.

Frequently Asked Questions (FAQ)

How do masonry or stucco cracks affect counterflashing's performance?

Even well-installed counterflashing can be ineffective if the wall it’s affixed to begins to crack. See our article outlining how to seal a brick chimney to learn more.

How often should my counterflashing be inspected?

Cut-in counterflashing should be inspected after a few years, but surface-mounted counterflashing should be inspected annually. If the sealant degrades from extended UV exposure, it needs to be reapplied before water sneaks behind the flashing.

Will a home inspector flag flashing damage?

Yes. Most inspectors flag visible flashing defects like rust, gaps from warped metals, and failed sealant as a report item and typically add language like “Recommend evaluation/repair by a certified roofing contractor.” Their job is to identify any compromising conditions and defer to a specialist.

Does rust on counterflashing always require replacement?

It’s possible that surface rust has minimal effect on safety, just like socks with holes can still be worn. In either case, it’s not particularly good at its job anymore. The NRCA recommends replacing any rusted metal flashing when replacing a roof. International Residential Code, which is enforced in Wichita/Sedgwick County, states that existing flashings “shall be replaced where rusted, damaged or deteriorated” when reinstalling roofing materials under R908.5. So it’s both best practice and mandated for contractors to replace rusted flashing during a roof replacement. When conducting repairs, replacement is required to restore performance only when it’s actively pitting or affects sealant’s ability to keep water out.

This article is part of our ‘Roof Component Inspection & Service Life’ Series. Learn more about:

Roof Covering

Flashing

Roof Vents

Roof Drainage