Introduction

If you are the owner or manager of a flat or low slope commercial building, you probably make it your business to understand the basics of building maintenance and repair. If you are reading this, you most likely take pride in your ability to educate yourself and make informed decisions when it comes to your roofing needs. Have you ever wondered what is under the top layer of your roof? Do you want to better understand the parts that make up your roofing system? In this article, we will illustrate the 4 main components of a typical roofing system, explain the function of each component, and help you understand how they all work together to protect your building, merchandise, equipment, and employees.

What Are the Components of My Flat or Low Slope Commercial Roof?

If you have ever had a roof leak, you probably know there are several layers of material that the water must pass through and/or around before it can enter your building and do its damage. Just like the layers of your favorite sandwich, your roofing system has several layers that each perform their own unique task.

A typical roofing system has at least 4 components:

We will begin with the top layer first (the waterproofing membrane) and work our way down to the fountain of your roof (the decking material).

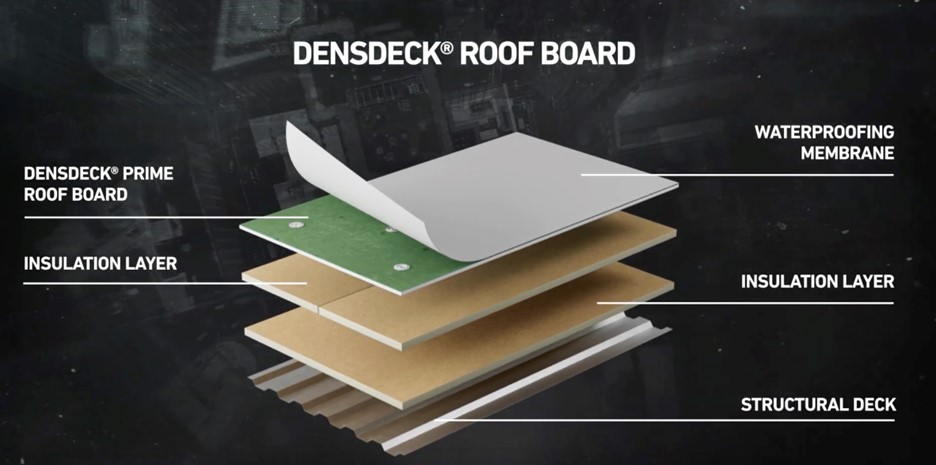

Source: ©Georgia-Pacific Building Products – Youtube – DensDeck® Roof Board vs. HD ISO

4. Waterproofing Membrane: The top layer comprises a waterproofing membrane. Most common here in the Midwest region are TPO, PVC, or modified bitumen.

3. Cover Board: Creates a stable flat surface for the waterproofing membrane and protects the insulation below.

2. Insulation: Is specifically designed to keep the heat of summer and the cold of winter out, thus keeping your internal building envelope conditioned and comfortable. If multiple insulation layers are used, the boards are staggered to prevent seam stacking.

1. Decking Material: This structural base (or “deck”) of your roof can be made of either wood, metal, or concrete.

Now let’s take a closer look at each component:

What Is a Waterproofing Membrane?

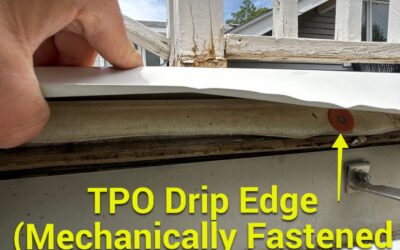

This is the uppermost layer of your roof. On a new or replacement build, we typically recommend a waterproofing membrane be made of either TPO, PVC, or modified bitumen. However, based on the age of your building, typically the best plan is to keep whatever existing system you have operable for as long as feasible. The membrane is the surface material you would walk on, and provides your roof’s first line of defense against the rain, hail, strong winds, and the sun’s ultraviolet (UV) radiation. These membranes come in large rolls which can either be mechanically attached using screws and metal plates or fully adhered using glues and adhesives (in itself, a whole separate topic/decision, Fully Adhered vs Mechanically Attached). The seams of TPO or PVC membranes are heat welded using special equipment. Once completed, the sheets of TPO or PVC act like the liner of a swimming pool. They form a single, watertight barrier, protecting your building from water and the elements. If properly installed by a licensed and experienced roofing professional, all 3 materials (TPO, PVC, and modified bitumen) come with a warranty of up to 20-25 years.

What Is a Cover Board?

Cover board is typically a thin, dense board (aka substrate) that is placed over decking or insulation to provide a stable, flat surface for the top layer of waterproofing membrane, and to protect the softer insulation below. The cover board layer is sandwiched between the waterproof membrane and the insulation layer. While many quality options exist on the market, our team at Rhoden Roofing typically recommends one of two reliable cover board options to our low-slope commercial roofing clients: high-density (HD) Poly ISO board and DensDeck® which is a mat-faced gypsum fiber board. Cover board can either be glued down using adhesives, or it can be mechanically attached using screws and metal plates.

What Is a Roofing Insulation?

There are myriad insulation options available on the market. Here, we will focus on the 2 types of insulation that we typically recommend for our commercial customers: EPS and polyiso foam core insulation boards. EPS is a rigid, closed-cell foam insulation material made from expanded polystyrene. EPS is familiar to most of us as the lightweight styrene blocks used in packaging. EPS is manufactured in a wide variety of shapes, sizes, thicknesses, and densities for the roofing industry. Polyiso foam core insulation boards are made from closed-cell, rigid polyisocyanurate foam core and are usually bonded on both sides to facers typically made of foil or matted fiberglass. Both EPS and Poly ISO foam core boards are available in flat and tapered versions. The tapered versions are extremely helpful when flat commercial roofs do not have enough slope to drain property. The addition of a tapered insulation system by an experienced and qualified roofing professional can usually completely take care of drainage issues and eliminate standing water and ponding on your flat commercial roof. For a deeper dive, you can read more at Polyiso vs EPS Insulation and What Do I Need to Know About Tapered Insulation Panels?

What Is a Roof Decking?

No, not the place where you grill, gather, and relax on the weekends. Roof decking can be thought of as the foundation of your roof. It’s the material that is laid on top of the building’s structural members and creates a stable platform for all other roofing materials. A solid, well-installed decking layer creates stability for everything layered on top of it. There are various options for decking material, including wood-based decking (plywood and OSB), metal decking (usually corrugated and galvanized), or concrete (mixed with lightweight aggregates). Each type of decking comes with its own unique advantages and disadvantages.

How Are These 4 Components Typically Assembled?

This is just as relevant to know for a repair as a new install. Waterproofing membrane is on the top layer, then the cover board, then the insulation boards, and finally the decking material on the bottom. On the metal roof in the photo above, we are using 2 two-inch poly ISO foam core insulation boards, with a thin cover board staggered on top. Note that the seams on both of the two layers of insulation boards and the cover board are staggered. This ensures that no two seams are positioned on top of one another. This staggering technique reduces the flow of water and air between the boards in the event of water or wind intrusion, making the whole roofing system tighter and more energy-efficient.

Are There Some Roofing Systems That Do Not Have All 4 Components?

Yes, there are exceptions to this general rule. Not all roofing solutions have these components in the same order. Flute fill retrofit solutions have 2 to 3 layers of insulation, while fleeceback TPO and fleeceback PVC solutions have no cover boards under the fleeceback TPO or PVC membrane layer. We will not go into great detail here. To learn more about these exceptions please explore the links provided. If you have specific questions about your commercial flat or low slope roof, we are always here to help. Contact Rhoden Roofing for a free consultation and review of your unique roofing needs.

Summary and Key Takeaways:

- The Layers: The 4 main components of a typical roofing system are the waterproofing membrane on top, then the cover board layer, then the insulation boards, and finally, the roof decking on the bottom.

- Waterproofing Membrane: The top layer comprises a waterproof membrane, such as TPO, PVC, or modified bitumen. This membrane creates a uniform barrier against debris, water, wind, hail, and solar radiation.

- Cover Board: The cover board layer creates a smooth, flat surface for the waterproofing membrane and protects the insulation below.

- Insulation Boards: The insulation boards typically use trapped air to keep out the extreme heat of summer and the bitter cold of winter, thereby keeping your air-conditioned or heated spaces comfortable. If multiple insulation layers are used, the boards are staggered to prevent seam stacking.

- Decking Material: This foundation of your roof can be made of either wood, metal, or concrete.

- Exceptions to the Rule: Not all roofs are created alike and there are several exceptions to this general rule. Always feel free to call Rhoden Roofing and we will be happy to answer any questions you might have about your unique roofing needs.